DIY Car Repair Tools – Torque Wrench

This is Part 1 in our DIY Car Repair Tools series.

Are you fed up with the constant trips to the mechanic every time your car needs a repair or maintenance task? It’s frustrating, time-consuming, and not to mention, expensive.

But, what if you could save a ton of money by doing your own car maintenance and minor repairs? Many tasks are easier than you think. All you need is a good basic set of tools.

In this article, we’ll introduce you to one of the most essential tools that every DIY mechanic should have in their arsenal – the torque wrench. We’ll explain how it works, why it’s necessary, and how much you should expect to spend on one.

What Is a Torque Wrench?

A torque wrench is a specialized tool that enables an assembler of virtually any type of mechanical equipment to consistently install fasteners (nuts, bolts and screws) to predetermined tightnesses. This predetermined tightness for any fastener is called its torque specification.

And why is this important? Engineers have found over decades of design experience that tightening a fastener to the proper torque is essential for proper function of the bolted joint.

Every automobile, truck, and motorcycle manufacturer, plus numerous other industries, find abundant use for torque wrenches. Repair and rebuilding shops for these machines likewise use these devices. But their use by a DIY mechanic is far less common.

Why Are Torque Wrenches Necessary?

All types of machinery (including all vehicles) have simple to complex bolted joints. These joints are designed to enable them to be assembled, remain assembled and subsequently be disassembled at some future time for maintenance and repair.

During the design process for any of these complex machines, the engineer determines the loads (forces) acting on every bolted joint. Using these load values, the sizes and types of fasteners are selected. Then the required tightness for each bolt is determined. This tension in each bolt ensures that the joint can withstand all applied loads anticipated over the lifetime of the machine.

The tightness required for each bolt establishes the required torque value. Then during the assembly process, a technician will use a torque wrench to tighten all the fasteners to their required torque specifications.

Note that in mass-produced machines such as automobiles, proper torque will often be applied to each fastener by a robotic device rather than by an actual technician.

Related: DIY Auto Repair Tools – The Socket Wrench

Does the DIY Mechanic Need a Torque Wrench?

The answer is, yes! Many jobs you may do on your vehicle will necessitate the use of a torque wrench.

Examples include installing wheels, attaching brake calipers, replacing suspension elements, installing a cylinder head, replacing spark plugs, installing aluminum camshaft covers, installing a new clutch, etc.

Any engine rebuilding work such as replacing pistons, connecting rods, main bearing caps, cam bearing caps, flywheel bolts, etc. also necessitate the use of a torque wrench.

The common factor with these parts is that they each will experience very high loads, as well as dynamic loads (forces which repeat cyclically during vehicle operation), over the life of the installation.

Torque Wrench Units of Measurement and Accuracy

Fastener torque is specified in a unit consisting of a force and distance. The most common units of measurement are pounds-feet (lb-ft) and Newton-meters (N-m).

- Lb-ft is the SAE convention used primarily in the United States.

- N-m is the metric convention somewhat common in the US but primarily used in other countries.

To convert from one to the other, use this relationship: 1 lb-ft = 1.35582 N-m. Often quality torque wrenches are marked with both units of torque for convenience.

The common standard for accuracy of torque wrenches is ±4%. The lower the percentage, the more accurate a torque wrench is.

Most torque wrenches, even the less costly ones, are more accurate than this standard. When you buy a torque wrench, its accuracy is generally stated on the package.

Types of Torque Wrenches

Most torque wrenches are similar to 1/4″, 3/8″, 1/2″ or 3/4″ square drive ratchet wrench designs. As with any ratchet wrench, a socket (SAE or Metric size) is installed on the wrench and then the wrench is used to perform the final tightening of the fastener.

Different types of torque wrenches include:

Click Type

The most common type of torque wrench, a click type is tubular in shape and incorporates a rotary adjustment ring around the handle end of the wrench.

This lockable ring can be rotated to bring its associated pointer (or numbered scale) to the desired torque value inscribed on the wrench handle. When tightening the fastener with this wrench, an audible ‘click’ will be heard and felt when the desired torque is attained.

Following use, this type of wrench should be readjusted to the lowest torque value on its scale. This sets the internal spring at its lowest compressed dimension thereby reducing risk of that spring taking a permanent set.

See Also: Different Types of Floor Jacks

Beam Type

The beam type torque wrench is simple and reliable. It utilizes a tempered steel beam alongside a long torque indicator pointer. With no torque applied, the pointer will align with the zero torque value.

When the wrench is used to tighten a bolt, the beam bends and the tip of the pointer will move along a curved scale indicating the torque value. When the prescribed torque value is reached the mechanic simply ceases to apply force to the torque wrench. Due to this wrench type’s simplicity it does not tend to go out of calibration over time.

This type can be awkward to use because the pointer must be continually observed while in use. Often when working on a car, such a wrench is not convenient because space limitations prevent direct observation of the pointer and scale.

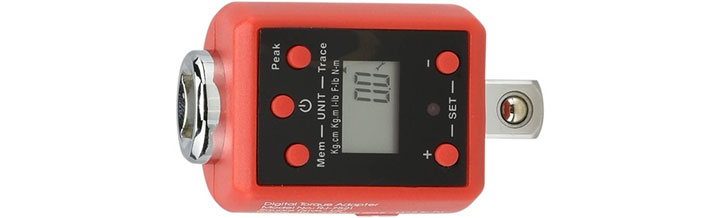

Digital Type

Digital torque wrenches have an electronic numeric display which can be preset to the desired torque value. In use when torque is applied, the display may switch (on some models) to show the gradually increasing torque value. And at the set value an audible tone will sound and/or an LED will illuminate to indicate proper torque has been reached.

Some models include a secondary indicator (beep, vibration, or light) to warn you that you are approaching your desired torque.

These wrenches use an internal torque sensing cell that should function reliably without change over many years of service. Batteries such as AAA or AA sizes will be required and should be removed when the wrench is not in use.

Split Beam Type

Split beam wrenches function much like the simpler beam types. They incorporate a stiff stationary bar alongside a specially dimensioned bending bar. Torque is set on a linear display by rotating an adjustment knob. That knob includes a locking feature so it cannot be turned during wrench use.

When torque is applied, a pointer climbs the scale to the set value. This must be observed while the wrench is in use. Some models, however, incorporate an audible or visible (using an LED) warning when the set torque is reached.

This type of torque wrench does not require resetting to the lowest torque value like the click type when not in use. Also the beam design tends to not go out of adjustment as rapidly as the click type wrench.

Dial Indicator Type

As the name implies, this type of wrench has a rotary dial like a typical gauge dial with a pointer to indicate torque values. A sliding ‘telltale’ marker located at the circumference of this dial can be set to the desired torque to help the mechanic see when the pointer reaches this value.

As with the beam type, this wrench requires continual observation during the fastener torquing process. Most dial indicator type wrenches have lower torque capabilities than other types.

Slip Type

Slip type torque wrenches will rarely be the DIYer’s choice. Such wrenches are each factory preset to a desired torque value and cannot be adjusted or reset by the user. In actual use, the wrench will slip at the preset torque value.

This operational capability prevents over-torquing a fastener and ensures simple and reliable use in an assembly line application where many fasteners must be installed in a fairly short amount of time.

Digital Inline Type

These devices are not actual wrenches but are small torque measuring devices that will have a female square drive on one side and a male square drive on the other. Such a tool can be installed on the end of a conventional ratchet or breaker bar.

Controls on the device enable easy setting of the desired torque. During fastener installation, the device will show ascending torque value during tightening and have an alarm plus an LED illuminated when the desired torque is reached.

These devices are electrically powered and will have one or more batteries. Some brands available online will use a watch battery such as the CR-2032. These batteries are small and will not likely provide a useful service life. Devices with one or more AAA batteries will offer longer service lives.

Not all of the available types of torque wrenches are listed here. Numerous other types of specialty torque wrenches have been developed. Generally such wrenches fit into specific niches like aircraft, gas turbines, mining equipment, heavy construction machinery, etc.

Do Torque Wrenches Require Maintenance?

Yes. Torque wrenches may periodically need recalibration and/or repair to ensure their accuracy and longevity. This is also why it’s so important to store the tool in its original case and never drop it.

Recalibration

If a torque wrench is used frequently, such as in an automobile repair shop, ISO 6789 requires that it be recalibrated every 5000 uses or every 12 months. For home garage use, a wrench will be idle most of the time. But it should be checked for proper torque at least annually.

A tool built specifically for checking torque performance of a torque wrench is made by the Steelman Company. This device, can be mounted in a vise and set to a desired torque. The torque wrench is then engaged to the 1/2″ drive socket on this device and its torque evaluated against the digital display on the tool.

A digital inline type of torque tool (see above) can be used in a pinch for checking your torque wrench for accuracy. Keep in mind that torque checking a wrench with another device will only be as good as the accuracy of that device.

Online you can find a number of DIY procedures for checking your torque wrench for proper calibration right in your own workshop. Using an accurate weight (such as a kettlebell or barbell plate) and a sturdy vise to anchor the torque wrench, very accurate calibration tests can be performed. Make sure the weight you use is actually the weight stamped on its side.

Repair

With the exception of the beam type of torque wrench, these tools are somewhat delicate. They will not endure being dropped on the concrete garage floor more than about once.

Should such an event occur, your wrench should be checked and recalibrated by a certified tool repair shop. Such testing and repair could cost more than simply replacing the wrench.

What Do Torque Wrenches Cost?

First, you will be best served if you own at least two torque wrenches. One should be a low range (3/8″ drive) wrench rated for perhaps 10 to 50 lb-ft. This would be a good wrench for installing new spark plugs.

The other wrench should be larger (1/2″ drive) and have a range from about 50 lb-ft to 200 lb-ft. This wrench would work well for installing lug nuts and bolts, brake caliper bolts, most suspension parts, a cylinder head, etc.

Torque wrench costs can range from comfortably inexpensive to unbelievably costly. For DIY jobs where you will probably only use the wrench maybe twenty-five times per year, lower priced torque wrenches will serve you well.

Here are some typical costs when looking online. Your auto parts store will probably charge a little more.

| Type | Cost | Note |

|---|---|---|

| Click Type | $50 to $500 | Expect to pay $100 to $150 for good quality. |

| Beam Type | $25 to $75 | |

| Digital Type | $100 to $2,000 | Expect to pay $100 to $200 for decent quality. |

| Split Beam Type | $200 to $350 | |

| Dial Type | $75 to $600 | Good quality for about $250. |

| Slip Type | $200 to $600+ | Not typically for DIY use. |

| Digital Inline Type | $50 to $200 |

Where To Buy a Torque Wrench

Various online sources such as Amazon and eBay offer torque wrenches.

Harbor Freight, often thought to provide lower quality tools, has a nice line of torque wrenches at reasonable prices.

Your local automobile parts stores (Advance Auto, AutoZone, CarQuest, NAPA, O’Reilly, etc.) as well as Walmart, Home Depot and Lowe’s all sell these tools.

Using Your Torque Wrench

- If the wrench can be set to a specific torque, set it as required and lock the setting if a locking feature is available.

- Snug the fasteners down with a conventional wrench. Never use your torque wrench for loosening bolts or for running them down to the snug condition.

- With the torque wrench, apply force smoothly until the fastener begins to turn. Continue to rotate the fastener slowly until the set torque is reached. The ratchet head of a click type torque wrench will ‘pop’ over when the set torque is reached.

- Once the fastener is tight, resist the urge to immediately check it with a second application of torque Doing this can over-torque the fastener.

- Some fasteners require retorquing after a short period of vehicle operation. Engine head bolts may require this. Your shop manual should provide guidance in this regard.

- DIY Car Repair Tools – Floor Jack and Jack Stands - Dec 12, 2023

- DIY Car Repair Tools – Socket (Ratchet) Wrench - Nov 9, 2023

- DIY Car Repair Tools – Torque Wrench - Apr 20, 2023