Transmission Shift Solenoids (Function and Failure Symptoms)

To understand transmission shift solenoid symptoms, it’s important to understand why and how automatic transmissions shifted BEFORE there were solenoids, and why solenoids were added to begin with.

How Planetary Gearsets Work

Transmissions and transaxles that shift automatically (CVT units not included) have one or more planetary gearsets at the heart of the unit. Those gearsets, along with driving and holding members like brakes and clutches, provide the different gear ranges, including reverse.

A simple planetary gearset consists of a sun gear, a planetary carrier with several small gears that rotate around that sun gear, and a ring gear that encircles the outside of the planet gears.

If you hold the planet carrier and drive the sun gear, the ring gear is driven in the opposite direction. That’s reverse.

Holding the sun gear and driving the ring gear drives the planet carrier to provide a gear ratio, and holding the ring gear while driving the planet carrier spins the sun gear as an output to provide a different gear ratio, etc.

The power coming from the engine is transferred through the torque converter, which has an impeller built into the torque converter shell and a turbine with matching vanes attached to the shaft that drives the innards of the transmission.

Any part of the planetary gearset can be held or driven. Clutches within spinning drums are hydraulically applied by a piston in the drum. Sets of static “braking clutches” or bands attached to the outside of the transmission applied by hydraulic pistons and act as “holding” members.

There are also one-way clutches that are mechanically applied by the direction of spinning elements.

The Hydraulics of a Transmission

The hydraulic element of a transmission begins with the fluid in the pan being drawn through the filter into the pump, which is driven by the outer shell of the torque converter. That shell is bolted to the engine’s “flex plate,” which is, at its center, bolted to the crankshaft.

It’s called a “flex plate” because as the pressure increases in the torque converter, its shell expands, and since that shell is bolted to the outside edges of the flex plate, that plate must flex with torque converter expansion. That’s why automatic transmission flywheels sometimes crack around the center.

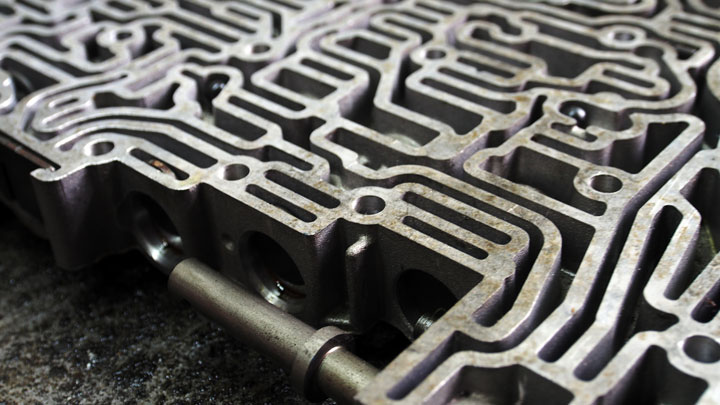

The hydraulic pressure created by the pump fills the torque converter and is available to the “valve body” as “line pressure.” That valve body is typically aluminum and is bolted to the transmission housing with a plate sandwiched between two gaskets with lots of little holes.

The valve body is machined with a complex set of internal passages that have spool valves and springs designed to direct hydraulic pressure to the various driving or holding members that interact with the planetary gear set(s) that provide the various gear ranges.

Hold that thought – we’ll get to the solenoids in a minute.

How Older Transmissions Shift

A “Governor” with an internal spool valve was originally designed to spin faster as the vehicle speed increased, and that governor operated its spool valve using centrifugal force.

As the spool valve within the governor changes positions with increasing vehicle speed, the fluid pressure passing through the governor is sent to other spool valves within the valve body, moving them against spring pressure and redirecting fluid to the driving or holding members.

Holding each gears longer as the transmission shifts is necessary when the transmission under hard acceleration or the vehicle is pulling a heavy load. This requires another pressure channel that opposes governor pressure. This pressure is referred to as “throttle valve” pressure.

On many older transmissions there is a “Modulator” valve with a movable core attached to an internal vacuum diaphragm within the valve. The core moves a simple spring-loaded spool valve within the transmission.

The vacuum feeding this modulator valve comes directly from the intake manifold. When the engine is loaded, the vacuum decreases, the core of the valve moves its spool valve within the transmission to work against governor pressure.

When throttle valve pressure increases, governor pressure is prevented from causing the next gear shift in the cycle until the vehicle speed (through the governor) increases governor pressure to overcome throttle pressure, forcing the shift to take place, only later than it would have with lower throttle pressure.

Just about all transmissions started moving away from vacuum modulators to use throttle position (through linkage or a cable) to control throttle pressure. Chrysler transmissions never used vacuum modulators, but most other platforms did initially.

Solenoids and Symptoms of Failure

The earliest transmission solenoids were designed to control the “Torque Converter Clutch,” which was a feature that began to appear in the late 1970s for the purpose of increasing fuel economy.

Most transmissions had 3 gears and “Overdrive.” In third gear, the torque converter clutch (TCC) would lock the torque converter shell to the turbine, causing a direct connection between the engine and the turbine shaft. When you tapped the brake, the torque converter clutch would release.

When the engine is cold, some vehicles won’t allow torque converter lockup because the torque converter generates heat while shearing the fluid when the TCC is unlocked, and the transmission fluid needs to warm up quickly for optimum transmission operation.

Those TCC solenoids can stick, holding the torque converter engaged when the vehicle stops, stalling the engine. That’s the first symptom we’ll mention that can be caused by a faulty solenoid.

If the solenoid fails to lock the TCC, fuel economy will suffer and the driver may not even realize the TCC isn’t locking unless they’re a stickler for watching the tachometer.

Solenoids and Vehicle Computers

As computers became the order of things on vehicles in the very late 1970s and early 1980s, engineers began to put computers in control of more and more components.

While the valve body still operated in much the same way, computer inputs and outputs were added. Pressure switches reported fluid pressure in various parts of the valve body. Those early switches were on-off switches but were soon replaced by one or more transducer(s) that reported pressure.

Throttle pressure and what was once governor pressure both became a computer controlled elements of the transmission by the pulsed application of a special solenoid. Shift solenoids could be applied to force fluid pressure increases in parts of the valve body.

Engine load, vehicle speed, transmission input and output shaft speeds, and throttle position suddenly became the inputs that determined transmission pressures, shift points, and even shift feel and quality. Many transmissions will momentarily “de-torque” the engine at the moment the transmission shifts to smooth the feel of the shift.

Some Asian vehicles used “fuzzy logic” to prevent transmission downshifts going up shallow hills with the cruise control engaged. Performance packages started appearing with switches on the instrument panel or shifter to change shift feel for those who liked crisp, hard shifts between gears.

Shift Solenoid Operation and Issues

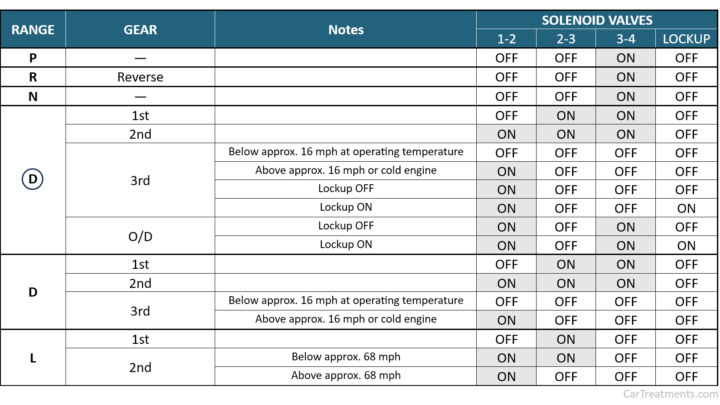

Different transmissions have different numbers of solenoids, and they don’t always work in the order we might think. People who think sequentially might logically believe that if a transmission has a Solenoid A, a Solenoid B, and a Solenoid C, that Solenoid A would trigger the 1-2 shift, Solenoid B the 2-3 shift, and Solenoid C would trigger the 3-4 shift.

That’s not how it works.

You can look at a simple shift solenoid chart and see how complicated the solenoid operation is between gears:

When solenoids fail, it depends on WHICH solenoid fails as to what happens as a result. One shift solenoid can fail and affect several gear ranges (see chart above). And not every symptom is solenoid related.

Solenoid related DTCs will point to the solenoid’s electrical circuit or a condition where there’s nothing wrong with the circuit but the PCM or TCM has commanded the solenoid to act but determines from input and output speed inputs that the commanded shift didn’t happen as commanded. This is classified as a “Performance Fault.”

Typically, when a solenoid fails you’ll notice a difference in shift feel or quality. The transmission may skip a gear, shift harshly, etc.

If power is lost to the transmission solenoids on newer vehicles, the Pressure Control Solenoid will default to high pressure to prevent the clutches from slipping and destroying themselves, and the transmission will default to a higher gear than first gear.

But on earlier transmissions, the transmission solenoids were fed by a fuse, and if that fuse is removed or blows for some reason, the transmission will take off in first gear and never shift.

Where Are Shift Solenoids Located?

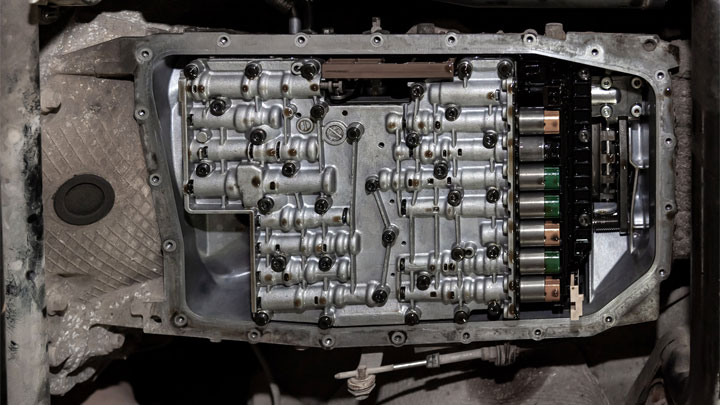

Solenoids were initially mounted on the valve body as separate components and most transmission shops would replace all the solenoids when the transmission was overhauled (this is a good thing) to keep the solenoids from causing problems, because often they do.

Many transmissions and transaxles still have shift solenoids mounted directly on the valve body but they’re often sold in clusters.

But on newer transmissions, solenoids are typically contained a single solenoid “pack” that contains all the solenoids. That solenoid pack on some Chrysler transaxles are external can be replaced without even removing the transmission oil pan, but most solenoid packs require draining the fluid to replace the solenoid pack, and in some cases, programming or learning may be required.

Some Honda transaxles typically have externally mounted single solenoids.

Asian transaxles (like Nissans) typically hardwire their transmission solenoids to ground and switch power to the solenoid from the PCM/TCM, but most other platforms power up the solenoids whenever the key is on and control them by switching the ground feed.

- Transmission Shift Solenoids (Function and Failure Symptoms) - Sep 20, 2023