5 Symptoms of a Bad Distributor (and Replacement Cost)

Is your vehicle currently running at less than optimal efficiency, or worse yet, not running at all? If so, distributor-related issues could possibly be to blame.

This critical component is perhaps the most valuable of all found within the modern automotive ignition system, yet can be the source of much hardship when in the midst of failure.

The following guide will detail the various symptoms associated with distributor failure, while also answering a number of the most common distributor-related symptoms.

What is a Distributor?

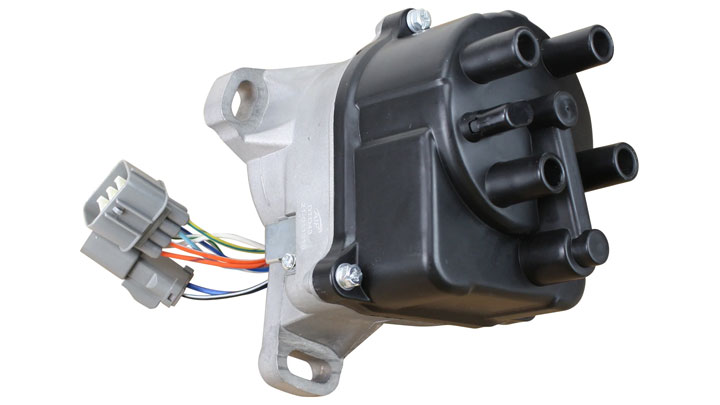

An automotive distributor is perhaps best described as an electro-mechanical device designed to deliver spark to each respective cylinder, in a precisely timed manner. This spark originates at an engine’s coil, before being “distributed” on a cylinder-by-cylinder basis.

The distributor itself is timed mechanically to the engine onto which it mounts, with a specialized drive gear. This drive gear is seated at the end of a rotary shaft that features a replaceable electrical contact known as a rotor button, at its opposing end.

The aforementioned rotor button is supplied with coil induced power that is then distributed to individual cap-mounted contacts for each respective cylinder in an expertly timed fashion.

Essentially, a distributor’s rotor button serves as a rotating electrical contact that supplies power to each spark plug wire, via intermittent continuity with individual cap-mounted electrodes.

As a rotor button’s finger touches the electrode for a specific cylinder, power is discharged through the corresponding plug wire to the cylinder’s spark plug.

Bad Distributor Symptoms

The failure or impending failure of a vehicle’s distributor is often attributed with a host of secondary symptoms, some of which tend to be rather severe in nature. Recognizing these signs often proves key when attempting to expedite replacement, and ultimately, repair.

The following are several of the most common symptoms associated with a faulty distributor.

#1 – Illuminated Check Engine Light

The failure of an engine’s distributor will almost always result in the illumination of a vehicle’s check engine light. This generally occurs as multiple misfire codes are logged and stored.

The check engine light itself will remain illuminated as long as these codes remain active.

#2 – Repeated Stalling

When a distributor fails, proper ignition timing is often lost. This creates a condition under which efficient engine operation is unobtainable. This will generally result in repeated stalling if the engine in question will even run at all.

#3 – Failure to Start

Much like described in the scenario above, a faulty distributor can quickly lead to a scenario in which an engine fails to start, or fails to remain running after its first few combustion cycles. Starting efforts will usually be accompanied by a volley of misfires.

#4 – Consistent Misfires/Backfires

If an engine’s distributor is no longer able to keep proper spark timing, consistent misfires and backfiring are to be expected. This will generally continue until the engine itself is no longer able to remain running.

A harsh vibration can also be felt, in most cases, when such symptoms are present.

#5 – High-Pitched Squealing

Though rare, a distributor’s internal bearings can fail in service. This leads to a distinctly audible squealing-noise that can often be heard over normal engine operation. This sound is often heard most prominently at start-ups.

Distributor Replacement Cost

Best places to order parts? See: 19 Best Online Auto Parts Stores

The cost of distributor replacement often varies from one model of vehicle to the next, due to variances in parts costs and labor requirements to complete such a repair.

However, you can generally expect to pay between $450-$800 to have your vehicle’s distributor replaced, with the vast majority of this cost being attributed to parts costs.

Repair

On the other hand, you can service a viable distributor for much cheaper. This involves replacing a worn or damaged rotor button, and distributor cap that is worn or has begun to crack. This repair can often be completed for less than $50 in parts and approximately $100 in labor fees.

Distributor vs Distributor Cap

It is not uncommon to hear the terms “distributor” and “distributor cap” used interchangeably. However, these two components are not actually one and the same.

More accurately, a distributor cap is an individual part of the greater distributor assembly as a whole. Perhaps better illustrating this concept is the fact that a distributor will not function without a distributor cap, nor would a distributor cap serve any purpose without a distributor.

The term “distributor” describes the drive assembly responsible for keeping proper spark timing in relation to base cam/crank timing. This assembly utilizes a coil (internal/external) and features an integrated timing advance mechanism.

Meanwhile, a “distributor cap” mounts to the top of the distributor itself, and features outlet contacts that allow power to be distributed to each respective plug wire/plug.

FAQs

Do All Vehicles Have a Distributor?

The common automotive distributor is becoming far less common with the passage of time. The vast majority of late model vehicles now feature individual coils for each respective cylinder, thereby negating the need for spark distribution via a traditional distributor.

Late-model distributorless ignition systems power these independent coils with high-voltage driver modules, designed to provide precisely timed spark.

This being said, there are many vehicles still on the road today that feature distributors. Because of that, distributor-related failures still bear consideration, especially among the aging sector of vehicles in service.

However, it is reasonable to assume that a time will soon come when distributors are made completely obsolete, much like earlier points/condenser type distributors of years gone by.

What Causes a Distributor to Fail?

A distributor can fail for a number of reasons. Some of the most prominent of these causes include eventual wear and tear to base drive components and bearings, as well as carbon build-up induced internal arcing.

Individual distributor-related components can also fail with age as well. Distributor caps can crack, allowing moisture intrusion, or incur electrode erosion. Likewise, rotor buttons can degrade with time, or even break entirely.

How Many Miles Do Distributors Last?

The average automotive distributor can be expected to last for the lifetime of the vehicle onto which it is equipped. However, much like any component, unanticipated distributor failure can and does occur, on occasion.

On the other hand, several distributor-related components are considered wear items, thereby requiring periodic replacement. This most notably includes a distributor’s cap, and rotor button, which typically require replacement every 20,000-25,000 miles.

Can a Car Run Without a Distributor?

An engine can, of course, run without a distributor. Most every late model vehicle is now engineered to forgo the use of a traditional distributor, in favor of a fully distributorless ignition system. In such instances, individual coils or coil packs are fired via a computer-controlled driver.

However, distributor integrity is still a deal breaker for vehicles engineered with a traditional distributor-based ignition system. Without a viable distributor, a system of this type is unable to generate a properly timed spark.

Can You Tell the Distributor is Bad Just By Looking at It?

It can be rather difficult to condemn a distributor based solely on a visual inspection. Unless visual oscillation of the distributor body itself is observed or excess lash in a distributor’s drive gear can be verified, you will be hard-pressed to spot impending failure.

On the other hand, you can condemn individual distributor-related components, such as a rotor button or distributor cap through a simple visual inspection.

Where Should the Distributor Rotor Point?

A distributor’s rotor should always point to the individual cap-mounted electrode that corresponds to the next cylinder slated to reach its top-dead center position. This places increased importance upon properly timing any distributor that is to be installed.

If you are to replace only the distributor’s rotor button itself, timing will be of little issue, as most rotor buttons feature a specially indexed detent. This prevents the rotor button from being installed incorrectly.

- 5 Symptoms of an EVAP Leak (and Repair Cost) - Apr 27, 2024

- P0480 Code (Symptoms, Causes, and How to Fix) - Apr 19, 2024

- Car Temperature Gauge Stopped Working? (Here’s Why) - Apr 15, 2024