DIY Car Repair Tools – Socket (Ratchet) Wrench

This is Part 2 in our DIY Car Repair Tools series.

The socket wrench is the unsung hero of any DIY mechanic’s toolkit. This versatile tool provides the power and access needed to loosen or tighten hard-to-reach nuts and bolts, making repair jobs much easier.

This article will go over how the socket wrench came to be, different types of socket wrenches, sockets, and adaptors, and how to go about buying a socket wrench set you’ll actually enjoy using.

See Also: Buying Your First Floor Jack and Jack Stands

The Socket Wrench – A Brief History

Threaded fasteners have been found in archaeological digs as far back as 400 BC. The Archimedes screw emerged around 234 BC as a rotating device that could pump water.

But it was not until the Industrial Revolution in the 19th century that threaded fasteners (nuts and bolts) were developed to hold bits and pieces of assembled devices together. Examples of such devices with multiple parts include early firearms, steam engines, paddle-wheel driven ships, railroad locomotives and simpler things like cast iron wood or coal-burning stoves.

Wrenches of various forms accompanied this process to tighten or loosen the nuts and bolts by gripping the square or hexagon-shaped fastener head designs that came into usage. Thus simple open end wrenches of all sizes abounded.

Sockets were soon designed to fit on bolt heads and were mated to lever arms so a mechanic could rotate and tighten fasteners.

The earliest sockets were mated to clock winding keys. Such keys fitted into a female recess or slot in the end of the socket opposite the end that gripped the nut or bolt. Keys were developed with crank handles or were L-shaped with long straight handles for increased leverage.

Such tools worked fine when there were no space restrictions around the fastener being installed or removed. But they were slow to use because each revolution of a bolt or nut could require the socket to be removed and repositioned several times.

In 1863 American inventor, J. J. Richardson, came up with a ratcheting wrench design. It was designed to hold a socket (or a square nut) and could turn a fastener with a back and forth motion of the wrench handle.

This ratcheting socket wrench did not need to be removed from the nut or bolt during the tightening or loosening process. Thus installation or removal of fasteners could be done with increased speed.

The ratchet wrench (or socket wrench) has since that time become a mainstay tool in any good mechanic’s tool box.

Types of Socket Wrenches

Over the decades numerous types of socket wrenches have been developed. The most common type consists of a ratcheting square drive to hold the wrench socket on one end.

Common square drive sizes include 1/4 inch, 3/8 inch, 1/2 inch and 3/4 inch. Larger sizes are also available for large machinery applications.

The handle or grip of the wrench can be made in a variety of forms each providing the means to hold and operate the wrench. A small lever is included near the socket to reverse the direction of operation of these wrenches.

The ratchet square drive will include one of several means to hold the socket in place during use. The most common is a spring-loaded ball that mates with a groove in the square recess in the socket to hold it in place.

Some wrenches, notably Craftsman, will use a button on the socket shaft opposite the end where the socket is mounted. This button is pressed to release the pressure on the detent ball to free the socket for removal.

Most DIY mechanics will have three different socket wrenches, the smallest a 1/4-inch drive, next 3/8-inch and then a 1/2-inch drive size. Larger sizes work well for larger higher torqued fasteners like wheel lug nuts.

Small sizes like the 1/4-inch have smaller ratchet heads enabling reaching tight locations more easily. Larger wrench sizes also have longer handles which through leverage, ease the loosening of larger bolts.

The most common wrenches have fixed (single position) wrench heads. These are typically the strongest designs. But flex or hinged wrench heads are available that enable increased ease of reaching fasteners in tight locations.

See Also: Types of Torque Wrenches

Types of Sockets

Once you have selected a socket wrench or two you will obviously need some sockets to turn those nuts and bolts. There are a wide range of sockets in 1/4, 3/8 , 1/2 and 3/4 inch square drive configurations.

Sockets for SAE and Metric fastener sizes are available. In fact, a basic socket wrench set will generally include a variety of sockets for hex head nuts, bolts and will often include both SAE and Metric sizes.

Separately purchased sockets can be bought with the following special interfaces to fasteners:

- Allen (hex) head sockets

- Torx sockets (male or female)

- Phillips head screw sockets

- Deep sockets (for longer stud situations and lug nuts)

- Spark plug sockets with internal rubber plug holder

- Swiveling spark plug sockets with magnetic spark plug holder

- Pass through sockets (requiring a special socket wrench)

- Flexible alignment sockets including U-joint types

- Impact sockets (essential for impact wrench use)

- Magnetic sockets which will secure a steel fastener to help install it on a distant stud

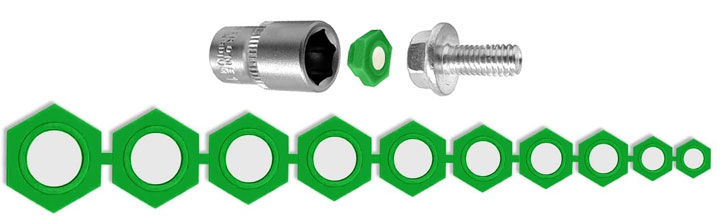

6 Point vs. 12 Point Sockets

These two terms will pop up when buying hex sockets. The terms refer to the number of fastener gripping surfaces in each of two different hex socket types.

A 6 point socket has 6 gripping surfaces; a 12 point has 12 surfaces. 6 point sockets give a wider grip surface to the nut or bolt but are not as easy to maneuver to grip the fastener as a 12 point socket.

Also a 6 point socket will have a thicker wall than a 12 point socket. For this reason a 12 point socket will generally fit into a smaller space than the same size 6 point socket. But 6 point sockets lessen the chances of rounding off a nut or bolt.

Socket Wrench Adapters

Specialized adapters are available for socket wrenches which will enhance ease of use in numerous different situations. The following are examples of such devices:

Straight Extensions

These are available in a number of different lengths and enable tightening or loosening a fastener that is located a distance from the wrench itself.

Common extension lengths include: 3″, 6″, 9″, 12″, 18″ and longer. Extensions can be “stacked” end-to-end to enhance reach.

Flexible Extensions

These utilize a flexible shaft of torsionally wound steel wire. Use of such a device enables smoothly turning a fastener that is not aligned with the socket wrench head.

Flex extension lengths include: 3″ up to 12″. These are suitable for moderate torque fastener installation.

Long flex extensions can be used for turning bolts that are as much as 90 degrees out of alignment with the socket wrench. Shorter flex extensions will not bend to that extreme.

Universal Joints

These enable access to fasteners that are not in perfect alignment with the socket wrench. U-joints are available in all square drive sizes. These adaptors are very strong and can be used for relatively high torque applications.

These adapters work for small angle misalignments up to and including about 12 degrees. When torque is applied through a U-joint adapter there is some tendency for the socket to pop off the bolt head.

Square Drive Size Adapters

These adapters enable one ratchet wrench (1/2″ drive, for example) to use smaller or larger drive size sockets. Such adapters enable a small socket wrench to drive a much larger socket.

This can be extremely handy in tight space situations. Adapters are available in all male/female square drive sizes.

Magnetic Socket Inserts

Offered in many different socket sizes, such magnets can be pushed into the bottom of a socket and will hold a steel nut in place for a remote installation. Inserts can be removed when not required.

Buying a Socket Wrench

Unless you are adding a socket wrench to an existing set of tools it is unlikely you will purchase a socket wrench alone. Your first socket wrench will likely be part of a socket wrench set. Many wrench sets will include just one wrench, but sets with multiple wrenches are quite common.

Socket wrench sets of a quality level suitable for the typical DIY guy or gal can be found at many good hardware stores.

- Ace Hardware, for example, features Craftsman socket sets and accessories.

- Home Depot and Lowe’s Home Improvement are also two good sources.

- Auto parts stores also will offer quality socket wrench sets but generally will lack the variety offered by a typical big box store.

Online, Amazon is a good option for such tools as well and you can find a set for any budget level. Here are a few good options:

- AFFORDABLE: Amazon Basics 201-Piece Mechanic’s Tool Set

- MODERATE: DeWalt 192-Piece Mechanic’s Tool Set

- MODERATE: Gearwrench 243-Piece Mechanic’s Tool Set

- MODERATE: Craftsman 262-Piece Mechanic’s Tool Set

- HIGH-END: Not necessary unless you work professionally as a mechanic or just want the best of the best, but brands to consider would be: SK, Proto, Wright, Sunex, Matco, and Snap-On among others.

Should you be a DIYer who intends to maintain and repair your car, outboard engine, motorcycle, lawnmower or any of a number of household devices and machines a socket wrench set will prove to be of infinite value for the work that lies ahead.

- DIY Car Repair Tools – Floor Jack and Jack Stands - Dec 12, 2023

- DIY Car Repair Tools – Socket (Ratchet) Wrench - Nov 9, 2023

- DIY Car Repair Tools – Torque Wrench - Apr 20, 2023