DIY Car Repair Tools – Floor Jack and Jack Stands

This is Part 3 in our DIY Car Repair Tools series.

Any car owner who desires to embark on DIY automotive maintenance or repair will need at least a floor jack and a set of jack stands as well. How come?

The typical car or light truck has many bits and pieces underneath that will one day need repair or maintenance (ie: brake pad replacement), so having a floor jack (or even two in some cases) can be immensely helpful. In this article we will take a look at floor jack and jack stand types, how to use them, where to buy them, and what they might cost.

See Also: DIY Car Repair Tools – Socket Wrench

The Floor Jack

A floor jack is a device that enables lifting heavy loads. In this discussion we are primarily interested in floor jacks that are specifically designed to lift at least one corner of an automobile or light truck.

Such jacks are configured with casters to enable easy movement on a flat concrete garage floor. They are not configured for use on rough or slanted pavement or in soft ground conditions like your side yard.

The most common floor jacks are self-contained, hydraulic and can be hand operated. These jacks will include a lift pad (or saddle) shaped to enable supporting different shapes of a car’s structure without slipping off.

The lift pad may include a non-slip moderately hard rubber face to help grip the contact surface on the car without causing damage.

Such jacks are operated by a long tubular handle that must be inserted into a fitting on the jack. Pumping this handle up and down applies hydraulic force to the lifting saddle and up it goes.

To lower the jack, the user would typically twist the handle counter-clockwise, which opens a hydraulic valve. When pressure is released, the jack saddle will descend at a speed consistent with how far you have opened this valve. With a little practice a smooth slow descent which is preferred can easily be attained.

Similar in function to hydraulic floor jacks are airbag (or air cylinder) operated jacks. More costly than the hydraulic types, these jacks require shop air to inflate the airbag (or extend a cylinder) which is doing the lifting. The typical DIYer who does not have a compressor in the garage will not be using this type of floor jack.

A third type of jack is the screw-driven scissors jack. This type uses a rotating screw to provide lifting force. Typically inexpensive to buy, such jacks can be awkward to use and keep stable beneath a vehicle during the jacking process.

When collapsed to the lowest position they also may not be low enough to fit beneath a modern sedan.

The jacking mechanism provided with this type is exposed and may be subject to corrosion and the collection of abrasive dirt over time which will shorten its service life. While such a jack may be useful for emergencies, for frequent car maintenance and repair this type is not recommended.

Read Also: DIY Car Repair Tools – Torque Wrench

Jack Stands

While at your favorite tool store picking out your floor jack, I recommend you also purchase at least two jack stands.

What in the world for? Simple. You cannot safely work beneath your vehicle while it is supported by a floor jack alone.

Jack stands are a convenient secure way to support your vehicle while you work there. Most jack stands are of welded steel construction with four supporting legs. Three-legged stands are less common but have the advantage of sitting in a stable position on an uneven surface. Even less common are the tubular support jack stands that use a flat support in contact with the garage floor.

Most jack stands incorporate a center column with a steel pad on top to support your car at suitable lift points. The center column is adjustable for height. In use the center column height is set while the car is supported by the floor jack. The jack stand is then slid beneath the car, aligned with the lift point and the floor jack slowly lowered.

Some jack stand types can be raised to position beneath the car. I find this awkward and potentially risky should the floor jack suddenly decide to collapse.

When supporting a vehicle a concentrated load (or point load) will be applied. Such a load can split a brick or concrete block potentially leading to an unhappy outcome. Always lift your vehicle with a suitable automotive jack and support it with appropriate load-rated jack stands.

Floor Jack and Jack Stand Load Ratings

Floor jacks and jack stands can be purchased with different load ratings. These devices should be sized for your heaviest vehicle. To determine the jack stand rating suitable for your vehicle, determine the weight of the heaviest car or truck in your garage.

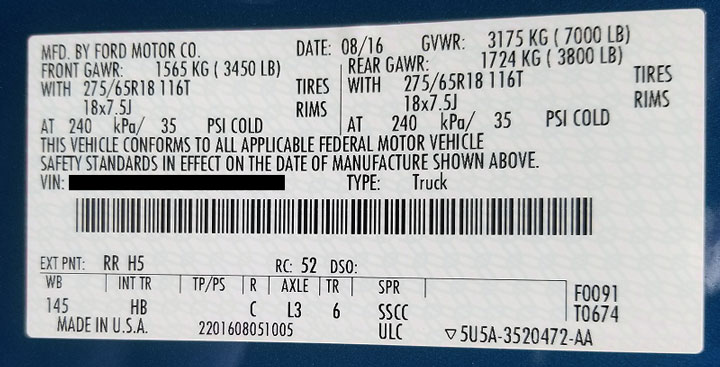

This weight (GVW, Gross Vehicle Weight) can be found on a specification label located on the driver side door post. Find that weight and then purchase both a floor jack and jack stands (at least two) with that load rating.

Some recommend the floor jack and jack stands each be rated at 3/4 of the GVW of your heaviest vehicle. While a pair of jack stands will never support 100% of the vehicle at one time, the more conservative approach is to use the full vehicle weight when deciding on floor jack and stands load ratings.

Floor Jack Accessory – Lift Pads

Most floor jacks out of the box will not include a hard rubber lift pad. Such a feature helps prevent the jack’s lift saddle from slipping off the lift point on your vehicle. When looking for this optional accessory, the best pad will have these features:

- It will nest inside the lift saddle on the jack.

- It may include a vertical slot to enable it to fit around frame flanges

- It will be hard enough to not collapse under the lifting load.

Bottle Jacks

A brief word about bottle jacks. These are cylindrical hydraulic jacks for unusual condition lifts. For example, a bottle jack can be useful for applying a temporary lifting load to an engine or transmission.

But for initially lifting your vehicle off the garage floor they are relatively impractical due to their height.

The shortest available bottle jack will rarely be less than 8″ tall. The small diameter of the lifting face on top of the bottle jack piston may make it unstable when lifting against a metal surface.

Your first jack for garage use on your car should be a floor jack as described above, not a bottle jack.

Using the Floor Jack and Jack Stands

Related: How to Use a Floor Jack Like a Pro

Now you are ready for your first use of these tools. If you are just preparing to work on one wheel, for example, the left front, you may find lifting the entire front end will give you better access around that wheel.

Before beginning the jacking process, put your car’s automatic transmission in ‘park’ or its manual transmission in gear. Then place suitable chocks in front of and in back of the wheels opposite the end you will be lifting.

Locate the lift points on each side of the car nearest the end you want to lift. These will generally be the jack points along the left and right side frame rails. At the front of many cars just ahead of the engine there also may be a convenient single point for lifting.

Consult your owner’s manual for the jack point locations. Lifting at other locations could cause structural damage to your vehicle.

Set a desired height on each jack stand to be used. Lift the car to about 1 inch above the jack stand height. Slide the stand to a location suitable for support of your vehicle and gently lower the floor jack.

Repeat this process on the opposite side. If convenient keep the floor jack in place with a light upward pressure on the car just for safety considerations.

Never locate a jack stand beneath any flat expanse of sheet metal, composite (plastic) material or beneath the plastic front or rear bumpers. These areas are not designed to withstand heavy vertical loads. If in doubt about where to place a jack stand, consult your vehicle service manual.

Before going any further, with considerable firmness push the vehicle side to side. It should feel solid and completely immovable. If it moves around at all, something is wrong with your jack stand arrangement. This absolutely must be corrected before proceeding any further with your repair job.

Upon completion of the repair work, reverse the lifting procedure to remove each jack stand and then lower the vehicle gently to the garage floor one side at a time.

Where to Buy a Floor Jack and Jack Stands

Not surprisingly, you will find Amazon.com to be a good online source for floor jacks and jack stands. Other sources include Harbor Freight, Home Depot, Lowe’s, Costco, and your local auto parts stores.

While some may consider Harbor Freight to be a low quality supplier, their automotive tools and in particular jacks and their present line of jack stands are of very good quality and reasonably priced.

Before making a floor jack purchase remember to measure the distance between the point on your vehicle where you will lift it and the garage floor below. You will want a floor jack that when lowered will fit beneath this space.

A “low profile” floor jack is generally ideal for sporty cars or those that sit fairly low to the ground.

On the other end of things, if you have a truck, SUV, or Jeep that sits high off the ground, make sure the maximum lift height of the jack will be enough for your purpose. A specialty Hi Lift jack may be needed in some cases.

Floor jack prices can range from about $100 to $450 depending on type, brand, load rating, construction, and where you purchase from.

Jack stands are normally purchased in sets of two. Pricing can range from about $30 a pair to over $200.

Here are three excellent hydraulic jacks if you’re looking to purchase:

- Daytona 3-Ton Long Reach, Low Profile Floor Jack (via Harbor Freight)

- Arcan 3-Ton Quick Rise Aluminum Floor Jack (via Amazon)

- Torin Big Red 3-Ton Aluminum/Steel Floor Jack (via Amazon)

And three good quality jack stands:

- Torin Big Red 3-Ton Jack Stands (via Amazon)

- Esco 3-Ton Performance Jack Stands (via Amazon)

- Big Red 3-Ton Aluminum Jack Stands (via Amazon)

Storing Floor Jacks and Jack Stands

None of the commonly stocked floor jacks and jack stands are well-painted and/or rust-proofed. When rusted, these devices will lose their load capacity rating and become unsafe.

Because of that, these tools should always be stored indoors or in a dry garage.

- DIY Car Repair Tools – Floor Jack and Jack Stands - Dec 12, 2023

- DIY Car Repair Tools – Socket (Ratchet) Wrench - Nov 9, 2023

- DIY Car Repair Tools – Torque Wrench - Apr 20, 2023