8 Parts of an Automatic Transmission (and What Each Does)

Outside of your engine, the transmission is one of the most complex parts of your vehicle. But an automatic transmission doesn’t get half the attention of an engine, and it’s a shame because your vehicle’s tranny is a work of art that is a fantastic piece of innovation when everything is running correctly.

But what makes up this masterpiece, and how does each piece work together in this mechanical symphony? Keep reading to find out all the significant parts of an automatic transmission and what they do.

See Also: 7 Symptoms of a Blown Transmission

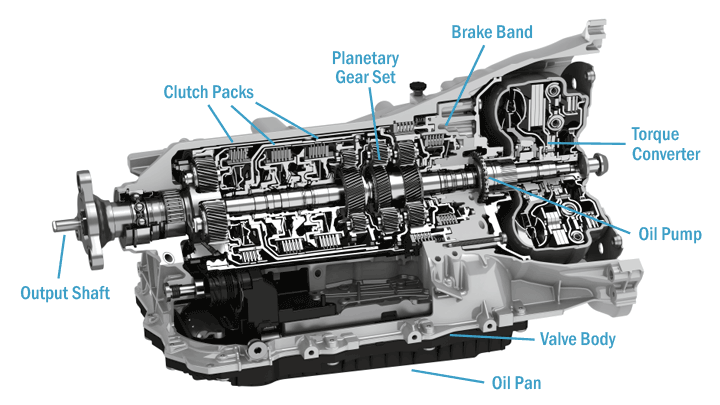

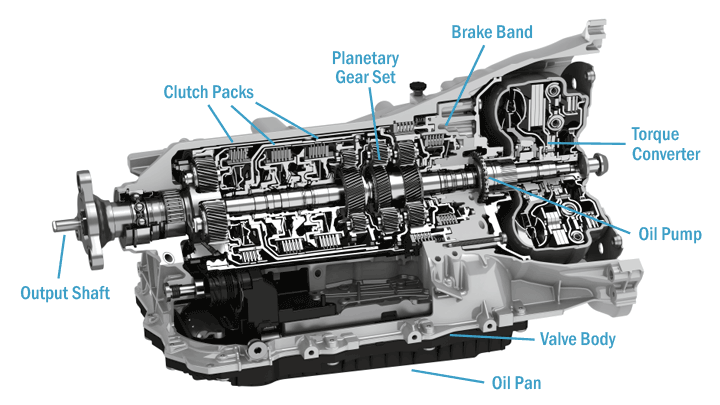

Automatic Transmission Components

A large number of components make up all the parts of an automatic transmission. Still, every automatic transmission has these eight main parts, and they are all integral to the proper workings of your transmission.

But you need to know more than just the part names to know how they get your vehicle moving.

#1 – Torque Converter

Automatic transmissions don’t have a clutch; instead, they have a torque converter. This replaces the clutch and performs the same function. Your transmission can’t shift gears while it’s still engaged to the engine; otherwise, it would snap gears. That’s why if you suspect that you might have a bad torque converter, you need to address it immediately.

Your torque converter allows your engine to stay running while disconnecting from the transmission – the equivalent of disconnecting your transmission to shift gears by depressing the clutch on a manual transmission.

The crazy thing about torque converters is that they don’t connect an engine to the transmission with a physical connection of nuts, bolts, or gears. Instead, it’s all through transmission fluid.

While a torque converter’s internal workings can be a bit complicated, it’s much like how you can power a fan by pointing another fan at it. Disconnect the first fan, and you can easily stop the second without hurting yourself.

Related DTC: Code P0740, Code P0741

#2 – Oil Pump

The oil pump inside of an automatic transmission works just like any other oil pump. It delivers transmission fluid from the transmission pan to the valve body, which directs it all the various components throughout the transmission as needed.

It’s not an overly complicated component, but it is an integral part of the system and is one of the few components in a transmission that will occasionally fail.

Read Also: CVT Transmission Life Expectancy

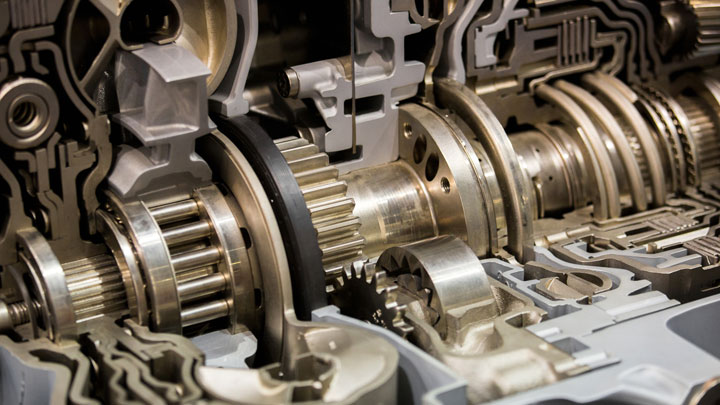

#3 – Planetary Gear Set

Unlike a manual transmission, which has a set of multiple gears that make up the gear box, an automatic transmission has a one or more (usually more) planetary gear sets.

Planetary gears have three sets of gears. The main gear is the sun gear, and it is in the center of the planetary carrier. The second set is the planetary gears. There are typically three or more of these gears and the mesh between the sun gear and the ring gear.

See Also: Straight Cut Gears vs Helical Gears

The ring gear surrounds all of the planetary gears with one ring, connecting the entire system and bringing it together. The system works by locking two of the three gear sets at a time. Since each gear set is a different size, this gives you a multitude of gear ratios by merely locking the other gears in place.

It’s an incredibly efficient system – and allows the transmission to utilize a variety of gear options without the setup that a manual transmission uses.

Related: Common Symptoms of a Blown Transmission

#4 – Clutch Packs

With a manual transmission, you manually select the gear you want to engage – an automatic transmission is a little more complicated. Instead of a manual shifter to get your output to the desired ratio, your transmission uses a clutch pack.

A clutch pack has multiple plates compressed together – when the valve body sends oil pressure to the clutch pack, it locks a certain number of clutch packs together, giving you your desired output ratio. Different amounts of oil pressure engage different quantities of discs, which gives your hub a different gear ratio.

Read Also: How a Clutchless Automatic Transmission Works

#5 – Output Shaft

Once your transmission has completed all of its internal magic, it delivers power to the driveshaft, which in turn supplies power to the hubs. But your transmission’s output shaft is what drives the drive shaft.

It’s typically not the most complicated component. On one end, you have a gear that connects to the transmission, and on the other end, you have a splined shaft that connects to the driveshaft via a yoke-type universal joint.

#6 – Brake Band

Brake bands serve one purpose – to temporarily hold planetary gears. They allow the engine RPM to get in line with gear ratio before releasing, which allows for smoother shifting.

Brake bands work much like drum brakes, with a piston squeezing the band around a drum. The harder the piston pushes, the more braking power is applied.

#7 – Oil Pan

Just like your engine has an oil pan on the bottom, so does your transmission. It does exactly what you think it would; it holds the excess transmission fluid (oil) for the oil pump to pull from when needed. It typically has a transmission fluid filter attached, either internally or externally.

It’s one of the most basic components of your transmission, but it’s also one of the components most likely to need repairs. The gaskets around the oil pan often leak transmission fluid and need to be replaced.

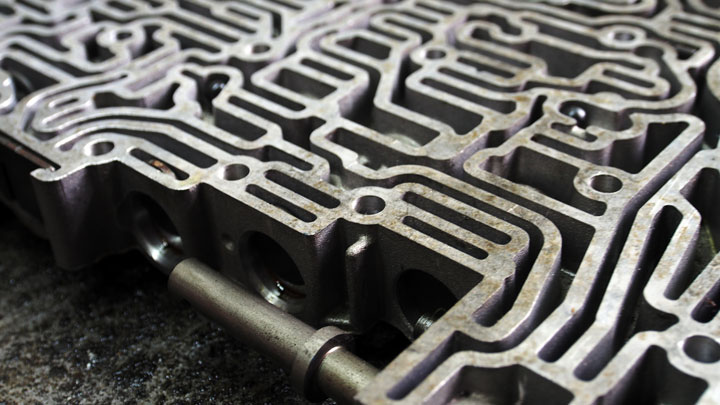

#8 – Valve Body

Your engine has an ECU, and your automatic transmission has a valve body. This component directs all the pressure from the oil pump to all of your transmission components to get the desired results.

From the torque converter to the clutch packs, nothing gets transmission fluid without the valve body telling it where to go.

In an automatic transmission, it’s controlled by sensors, which work directly with the transmission control module (TCM) to control where all the fluids are sent. It’s a complicated component, but it’s the most important one in your transmission.

See Also: ECU vs ECM vs PCM vs TCM

How an Automatic Transmission Works

Just because you have a basic understanding of all the parts of an automatic transmission doesn’t mean that you know how it works from start to finish. That’s completely normal.

Transmissions are complicated and technical components unless someone’s walked you through their inner workings; it’s hard to piece it all together. From the moment you put your car in drive, your transmission gets to work.

The first thing that happens is that your valve body receives a signal from the TCM telling it that it wants to move – and in first gear. The valve body then directs the correct amount of transmission fluid to your torque converter and clutch packs to put everything into motion.

Related: What Transmission Do I Have?

Of course, to do this, your oil pump has to kick on, taking fluid from the transmission oil pan and pushing them to the valve body, which directs it to the necessary components. Your planetary gear set then locks the ring gear, 1st gear, and gets everything into motion by delivering power to the output shaft.

At this point, your transmission hasn’t used the brake band. It won’t get used until you get past 1st gear, and it’s trying to shift as smoothly as possible. When it’s going to shift gears, your valve body directs fluid away from the torque converter, allowing your transmission to engage the correct planetary gear without a ton of force causing things to snap.

See Also: P0700 Code (Transmission Control Malfunction)

If it’s necessary, your brake band will then kick on when your torque converter reengages, allowing everything to get up to speed smoothly. It works the same way as your transmission shifts to a lower gear; the valve body just sends a different signal.

Here’s a good video showing how a vehicle’s automatic transmission works:

Is the Transmission Part of the Engine?

No, the transmission is a separate component from the engine in a vehicle drivetrain. While the engine and transmission work closely together, they perform unique functions.

The engine generates power by burning fuel to create motion, while the transmission takes that power and delivers it to the drivetrain, which then turns the wheels. This allows the vehicle to accelerate smoothly from rest and drive effectively at varied speeds.

Additionally, the transmission and engine are housed in separate cases, use different lubricating fluids (engine oil vs transmission fluid), and spin on independent axes when in the vehicle. The clutch or torque converter links the two components.

- P0521 Code (Symptoms, Causes, How to Fix) - Mar 22, 2024

- How to PROPERLY Clean 5 Types of Steering Wheel Materials - Feb 19, 2024

- What Should You Do If Your Check Engine Light Comes On? - Nov 6, 2023

when you park the automatic car . I would like to see the parking pawl illustrated

thank you in advance Roy

Sorry we didn’t get a picture of that one. The parking pawl looks like a gear around the input shaft of the transmission with a thick metal lever that fits into the slot between two teeth. It’s inside the transmission and there are some good pictures online. Here’s a great explanation with a video to show you how it works. https://youtu.be/i1gTXnkxhHE?si=FeWDR2vV-TtFyffa&t=67

Put to much fluid in the transmission of 97 mercury sable wagon. No matter the shifter position it is stuck in neutral. What’s wrong?

My 2004 Ford f150 will go in park, reverse, and neutral but won’t go into reverse, low, two, or one. What’s wrong

I’m learning tanks

Thank you very much I learn alot and I need more

May i use your diagram illustration in a youtube video i want to produce?

Thanks in advance

Gary

Yes, but please link back to this site when you do.