5 Symptoms of a Bad Motor Mount (and Replacement Cost)

A vehicle’s engine produces a lot of vibration when running. Without specific components called motor mounts (or engine mounts), the vibration would transmit to the entire car and make it very uncomfortable its occupants.

Learning to recognize the symptoms of a bad motor mount quickly will save you a lot of trouble in the long run. While the cost of engine mount replacement isn’t cheap, ignoring it can end up being a lot more expensive.

Bad Engine Mount Symptoms

#1 – Sounds of Repeated Impacts in the Engine Bay

When engine mounts wear out, one of the most common symptoms of this is noise in the engine bay. This can be in the form of clanking, banging, and any other sound that makes you think of an impact.

These sounds occur because the engine isn’t secure anymore. It shifts from side to side, bumping into the walls of the cradle.

#2 – Stronger Vibrations Than Normal

This is a common sign of a dying engine mount. Any excess vibrations in your car are caused by a failing mount.

When the rubber or dampening fluid of the mount wears out, or when the mount itself ceases to be secure, its ability to prevent vibrations is impacted severely. You will begin to feel the entire car shake and vibrate.

Related: Common Causes for Steering Wheel Shakes

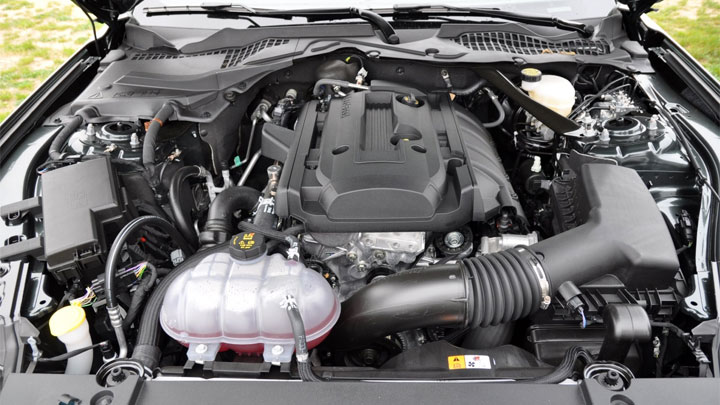

#3 – Engine is Moving Around

If your engine tends to move about in the bay, you have at least one bad mount. Keeping the engine secure is the primary function of the mount.

Worn mounts allow the engine to move in all directions. You can hear this movement when you accelerate and the engine vibrates more intensely.

You will typically hear impact sounds to accompany the unsecured engine. This can lead to a lack of safety in the cabin of the car. It can also lead to other delicate parts of the car being damaged such as when the radiator fan hits into the surrounding shroud.

#4 – Engine Slightly Tilted

When the engine of the car is secured using mounts, it is also aligned correctly. This means that the engine is on one level, without having a varying height throughout its cross section. A failing set of mounts causes the engine to droop to one side, or even to tilt.

This can be detected by listening for the sound of excess vibration in the engine bay. Check the engine out regularly and look for tilting.

Slight tilting doesn’t affect the capability of the engine, but the engine can actually flood and fail if it tilts too far to one side, leading to a breakdown. Always check and replace your mounts as needed.

#5 – Damage to Your Engine Block

This is one of the most extreme situations that can occur as a consequence of having a bad engine mount. If the mount breaks and fails catastrophically because of negligence in replacing it when needed, your entire engine is likely to start bouncing around.

At high speeds, this can result in the engine losing some of the most delicate parts due to it hitting surrounding areas. This can lead to a serious accident, resulting in major damage or even loss of life.

Motor Mount Replacement Cost

Best places to order parts? See: 19 Best Online Auto Parts Stores

The longer you wait to replace your engine mounts after the symptoms start, the more it can cost you. Prevention of a failed engine mount scenario is the cheapest and most effective method.

However, the cost of replacing a cracked or broken mount can range anywhere from about $250 to $600 based on your car’s size and requirements. For the price of parts, actual motor mounts themselves cost around $50 to $150.

The labor to install these mounts and correctly realign your engine costs more than the parts themselves. Expect to spend anywhere from $200 to $450 in labor to replace a motor mount depending on how difficult it is to get to.

Read Also: Strut Mount Replacement Cost

Keep in mind that you will often need to replace more than one engine mount so the actual cost may be more than specified above.

It’s a good idea not to skimp on quality when it comes to engine mounts. Either stick with OEM or an aftermarket brand with a good reputation.

How a Motor Mount Works

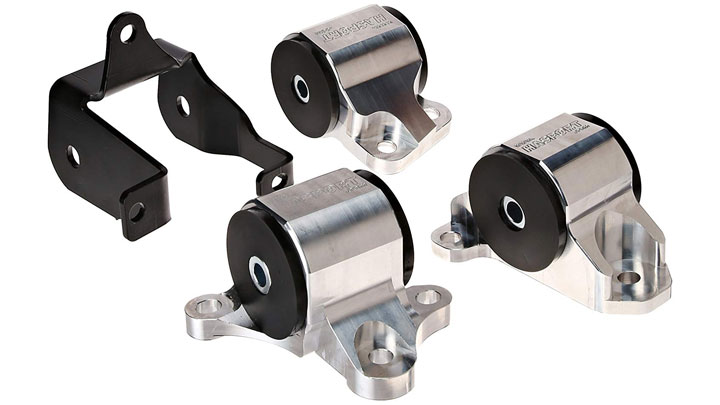

Motor mounts are small parts that attach the engine to your vehicle. Typically, up to four mounts are used to attach the motor to the frame of the car or the cradle of the engine. Your transmission uses mounts as well.

Most engine mounts have rubber in them to reduce the contact points of the metal of the engine with the body of the car. This helps reduce the vibrations of the engine and damage that follow from this.

Additional vibration dampening can be done by filling the mount with a liquid instead, which is a feature found on top of the line mount products and car models.

Vibrations in the engine block are the most common cause of damage to the most delicate parts of the engine. Excessive vibrations can cost you thousands of dollars in repairs. The purpose of an engine mount is to prevent these vibrations from transferring where they shouldn’t.

The engine block is secured firmly to the frame or sub-frame of the car body. Vibrations are dampened and don’t impact the other parts of the engine nearly as much. The connection between the engine and car body is maintained.

An additional function of the motor mount is that it prevents vibrations from reaching the rest of the car as well. All in all, beyond keeping your engine connected to the frame, mounts are the first line of defense against damage-causing vibrations in your vehicle.

See Also: Reasons Your Car Shakes When Accelerating

- Replace the Engine or Replace the Car? (11 Factors to Consider) - Apr 11, 2024

- Plastic Piece Dragging Under Your Car? (What It Is and What To Do) - Mar 21, 2024

- Timing Belt vs Timing Chain (What’s the Difference?) - Feb 27, 2024

Just got brand new tires and an alignment and now I have noticed that if I accelerate quickly a vibrating noise is coming from the front end, it sounds like from the engine area. I have a 2008 Honda Civic hybrid. Could this be the engine mount is off and it’s more noticeable since the rest of the car is now aligned properly? It doesn’t vibrate if I accelerate slowly, only if I press the gas decently hard to accelerate quickly. I don’t notice any noise when braking either and I never noticed this noise prior to the new tires and alignment. It doesn’t seem to be coming from any of my tires, it’s coming from the front end under the hood. I’m worried to keep driving the car, it seems fine other than the slight noise it makes but I don’t want to damage anything further if there’s an issue. Should it be safe to drive if I’m slow and careful? I just started a new job today and I don’t know how soon the shop can get me in with my new work schedule.

I would check to make sure the alignment shop tightened down all the eccentric bolts and tie rods. It sounds like something was overlooked during the alignment process.

Can’t say if it’s safe for sure, so use your best judgment there. I’d get it checked out by the original shop ASAP.

My 2001 Toyota Camry has a noticeable vibration when in park. It increases when the AC is on and in park. Once I put it in drive and start driving, I’m not sure if it goes away or I’m just not able to feel. I can feel it while idling at stop sign/light. Does that sound like motor mounts and should I drive it in this condition for long? I’ve changed the intake valves.

Could be a motor mount. That was my first thought when I read the symptoms. It’d be best to get the car checked out when you can.

Have a 2004 Toyota Camry, with the 24 valve V6. When turning to go around a curve or turn on to another roadway there’s a vibration that begins while turning in the right side. Once you complete turn vibration goes away, it does not happen when you make a left-hand turn, could this be a motor or transmission mount allowing extra vibration to transfer to the front passenger tire,

It could be, but I would actually check the wheels and suspension first. Make sure you don’t have a bad ball joint, a loose axle nut, or something like that.

We have a 2016 Subaru Forester. Was recently taken in to replace a ball joint control arm. While there they punctured the boot on the axle and had to replace that as well. Ever since then our car has vibrated, only when accelerating and will pull to the left also only while accelerating. Ive been researching and it sounds like an engine or transmission mount issue since its only when accelerating. First, does this sound correct? Second could this have been damaged while they replaced the control arm and/or front axle? Thank you!

I don’t know. I would take it back to the shop, as it’s possible they made a mistake when they replaced the control arm or axle.

No, that sounds like a failing axle. If they punctured the boot and immediately replaced the boot, while ensuring the correct amount of grease was in there, all would be well…but it sounds to me, given the timing and sudden steering issues, that they failed to address the axle boot.

Hello, We bought a brand wheelchair 2018 conversion van that started to have severe noises that sounded horrific. At times it sounded like heavy duty grinding. We took it to the dealership, and the mechanic told me it was the muffler vibrating, due to the wheelchair conversion. I took it to a shop where the muffler was moved slightly, but the noise continued, even worsened. I took it back to the dealer, where they identified a “tilting’ motor mount. They told us it would not be covered since the van had been converted. We called the conversion company and they said they would have the car picked up and repaired at one of their authorized dealers. We were told to no longer drive the car so they ordered a flatbed tow truck, but the guy from their authorized dealer drove the van to their shop which is a bit of a distance away. My question is what kind of damage should I expect on the engine since we drove it around for about a month since we were told it was only the muffler vibrating?

Not knowing the exact vehicle or problem I can’t say for sure, but if it’s just a loose or noisy motor mount I wouldn’t sweat it. Once the issue is addressed, I wouldn’t expect there to be any further damage.

I have a 2012 Jeep Cherokee. Long story short I have a new Jasper motor installed end of November by a mechanic. In February the dealership repaired all issues surrounding to the mechanic improperly installing the engine and not putting bolts back in my frame. Welding pieces together that they shouldn’t have. I was assured by the dealership that they went over it with a fine tooth comb. Today during inspection and me saying I hear a clunk noise since I picked it up came to tell me my left motor mount is leaking and would cost $800 for them to fix. The truck was driven 1000 miles since their work. Was this missed by then? Could it be that it went bad in the 1000 miles? Were they even touched when the engine was replaced?

Motor mounts secure the engine to the subframe, so yes they were touched when the engine was replaced. It’s hard to say if they missed it or if it started leaking after their inspection. Some vehicles with fluid filled motor mounts are prone to leaking.

Dealership ‘s during most any service inspection do not check engine mounts. I do not believe their is a schedule maintenance interval. Reason why there is no schedule you have no maintenance to perform on them. To tell you the truth 37 years as a Service Director at Dealerships do not recall replacing any unless the vehicle was brought over from our body shop

I am not aware of a scheduled maintenance interval on motor mounts either. However, some vehicles have recalls or technical service bulletins (TSBs) for motor mount degradation or excessive noise, vibration, and harshness (NVH).

For instance, the 2010-2013 Mazda3 and 2012-2013 Mazda5 had a TSB for a squeaky motor mount, as seen here: https://static.nhtsa.gov/odi/tsbs/2013/SB-10059437-0335.pdf

TSBs are not recalls, but a TSB on motor mounts for a given model will increase the likelihood that both the customer and the dealer would be aware of a possible motor mount issue and wish to have them inspected. Some components with a TSB will be covered under warranty for applicable vehicles once the customer complaint is verified.

I was told my Lexus engine mounts need to be replaced & the car is unsafe to drive. The car was serviced 5,000 miles ago at the Lexus dealer. Could they deteriorate that quickly or would there have been visual indications they were failing? The car has not had vibrations or noises

Why did they tell you they need replacing? Usually it’s pretty obvious when motor mounts are broken or deteriorated to the point of needing immediate replacement. They have done a test (putting foot on brake while giving it some gas) to see if there was too much stretch in them. This would cause the engine move, lift up, or even twist.

You can always take the car to an independent mechanic to have him do a quick look as a second opinion.

A lil over a month ago I bought a 2010 car at a dealership… 2 days after buying the car I had a vibration so I took it to my mechanic to find the ball joints were bad so I had them fixed in which the dealership that sold me the car did pay for, but I still had a slight vibration & just a few days ago it started clunking & I thought it was the struts but the dealership said they put new struts in so today I took it to my mechanic whom said the struts were fine & that the front motor mounts needed to be replaced…. Shouldnt the dealer had to fix such a safety issue before even selling the car?

They absolutely should have if you’re talking about a dealership. An independent used car lot would be different. But whether a dealership is selling a car as-is or labeled as certified pro-owned, they typically do a similar inspection and repair/replace any issues that show up. A failed motor mount would have been pretty obvious during the test drive. There is the possibility the mount simply had a crack in it (where it wasn’t noticed during the inspection) and then failed after you took possession. In either case, it sounds like this dealership is doing its best to fix the issues. If you don’t feel comfortable with the car, you may be able to convince them to take it back although you may need to contact the car manufacturer directly.