P0018 Code (Symptoms, Causes, and How to Fix)

Has your vehicle ever logged a timing-specific fault code, such as DTC P0018, that you found yourself perplexed by?

Keep reading to understand what exactly a P0018 code means, how serious it is, what causes it, and how to fix it… the right way.

What Does Code P0018 Mean?

Diagnostic trouble code P0018 is indicative of an out-of-time condition between an engine’s bottom (crankshaft), and top (camshaft) end rotating assemblies, as interpreted by a vehicle’s computer (ECM or PCM).

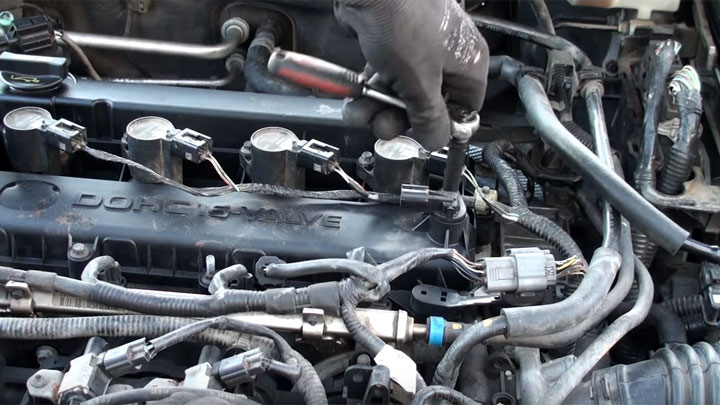

Timing data for each of the abovementioned rotating assemblies are recorded by specialized sensors, which include the crankshaft and camshaft position sensors.

An engine’s crankshaft and camshaft position sensors both read magnetic pulses generated from independent tone rings mounted to the ends of the crankshaft and camshafts, respectively. These pulses are tabulated by a vehicle’s ECM/PCM, allowing an accurate depiction of engine timing to be rendered.

Proper timing is essential to safe and effective engine operation. An out-of-time engine will not only run at less than peak efficiency but will also run the risk of piston-to-valve interference (interference engines).

An interference of this time can lead to catastrophic internal engine damage. Therefore, any timing-related engine issues should be taken extremely seriously.

In the event of DTC P0018, the affected vehicle’s ECM/PCM has determined that feedback signals from an engine’s crankshaft/camshaft position sensors are irregular and that they do not correlate as anticipated. This could be indicative of a number of underlying issues, some of which are more serious than others.

Of course, it is worth mentioning that many VVT-equipped engines accumulate faults of this nature when underlying variable valve timing issues exist. Therefore, troubleshooting of the VVT system in its entirety should be conducted on such engines, before assuming that a sensor or base-timing related issue exists.

Related: P0016 Code, P0017 Code, P0019 Code

Symptoms of Code P0018

Diagnostic fault code P0018 is often accompanied by a host of secondary symptoms, some of which tend to be more severe in nature than others. Recognizing these symptoms is the first step to forming a timely diagnosis.

The following are several of the most common symptoms associated with DTC P0018.

- Illuminated check engine light

- Crank/no start condition

- Reduced engine performance

- Intermittent stalling

- Erratic idle

Causes of Code P0018

Diagnostic fault code P0018 can be caused by one of many different underlying issues of varying complexity. Those that are familiar with the potential causes of this fault often prove more adept at executing a timely diagnosis and repair.

The following are several of the most common potential cases of DTC P0018.

- Stretched timing chain/belt

- Worn timing chain/belt tensioner

- Jumped timing

- Damaged crankshaft/camshaft tone ring

- Compromised cam/crank sensor wiring

- Faulty camshaft sensor

- Faulty crankshaft sensor

- VVT system failure

Is Code P0018 Serious?

Diagnostic fault code P0018 is generally regarded as being quite serious in nature.

This stems from the fact that a fault of this nature is typically associated with a host of secondary symptoms, many of which have severe implications for a vehicle’s overall driveability. The most severe of these symptoms can include engine stalling and engine crank/no start conditions.

Additionally, it is important to consider that several potential causes of diagnostic fault code P0018 point toward actual timing related issues, many of which originate at the timing chain/belt.

If ignored, a compromised timing chain or timing belt can break, causing catastrophic engine failure. Therefore, this fault should never be taken lightly.

In any event, the root cause of a vehicle’s P0018 diagnostic fault code should be thoroughly diagnosed and repaired as soon as possible. Doing so could quite possibly be the difference between prolonging your engine’s longevity, and suffering substantial damage in the long run.

If DIY repairs make you uneasy, schedule a service appointment right away at a reputable auto shop you know and trust.

How to Fix Code P0018

The following steps can be followed to assist in diagnosing and repairing the root cause of your vehicle’s P0018 diagnostic fault code. As always, consult your vehicle’s factory service manual for model-specific repair instructions before attempting any DIY fixes.

#1 – Check For Additional DTCs

Before beginning the diagnostic process, check for the presence of additional diagnostic trouble codes using your OBD2 scan tool. Any such codes should be thoroughly diagnosed before proceeding.

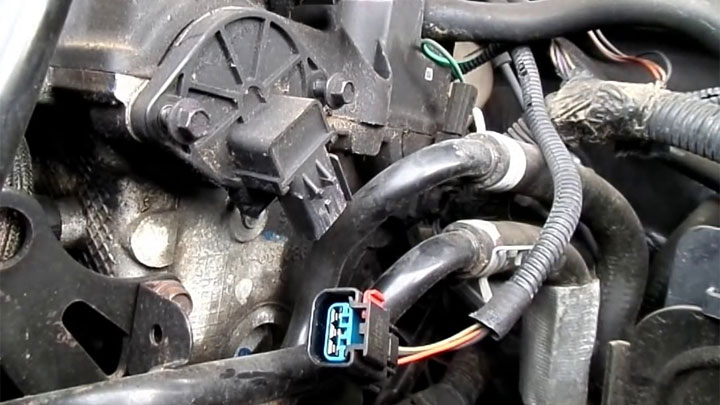

#2 – Inspect Cam Sensor/Wiring

Begin the diagnostic process by carefully inspecting the vehicle’s camshaft sensor and corresponding wiring connector for signs of damage. Likewise, check the cam sensor’s connector for any irregularities. Correct any such damage before proceeding.

#3 – Inspect Crank Sensor Wiring

Next, inspect the crankshaft sensor and all related wiring for signs of damage. Any irregularities should be corrected immediately.

#4 – Check Engine Oil Level

If your vehicle’s engine features variable valve timing, it is important to verify that your engine’s oil is filled to capacity, and is of the correct viscosity. A lack of proper lubricating engine oil is among the most common reasons for this fault in VVT engines.

#5 – View Live Crank/Cam Signals

If no obvious point of failure has been determined to this point, you should refer to the live streaming data from both the crankshaft and camshaft shaft position sensors. This can be done with the use of a professional-grade OBD-II scan tool.

Any irregularities pinpointed while graphing the signals from either circuit would be indicative of failure of the respective sensor or related circuit.

#6 – Perform VVT System-Specific Checks

If your vehicle’s engine features variable valve timing, additional troubleshooting of the VVT system should now be conducted, in the manner specified by the vehicle’s manufacturer.

#7 – Check Engine Timing

If your vehicle’s engine does not feature VVT, or if this system has been satisfactorily tested, you will need to inspect your engine’s timing chain/belt, as well as all associated guides.

Excess play in this assembly can lead to variance between top/bottom end timing, in turn leading to severe engine damage. Excessively worn components should be replaced immediately.

- P0480 Code (Symptoms, Causes, and How to Fix) - Apr 19, 2024

- Car Temperature Gauge Stopped Working? (Here’s Why) - Apr 15, 2024

- Ignition Coil vs Coil Pack (What’s the Difference?) - Apr 8, 2024