5 Advantages of Common Rail Diesel Engines (and 3 Cons)

Imagine your diesel engine becoming more efficient, powerful, and cleaner with just an upgrade in the fuel injection system. That’s what happened when common rail diesel engines came into the scene.

With a high-pressure fuel rail feeding individual injectors, you get precise control of fuel delivery – meaning better performance and fewer emissions.

It’s a leap from older diesel technologies where precision and control were harder to achieve.

Related: 10 Best Diesel Engines

Basics of Common Rail Diesel Engines

In understanding the evolution and operation of modern diesel engines, common rail technology plays a pivotal role. It significantly enhances engine performance through precise fuel injection while contributing to lower emissions and improved fuel economy.

History and Development

The concept of common rail injection dates back to the early 20th century, with the first significant use in submarine diesel engines during the 1910s.

Since then, advancements in technology have paved the way for its widespread application in various diesel engines, primarily to meet stricter emission regulations and the demand for better performance and fuel efficiency.

Key Components

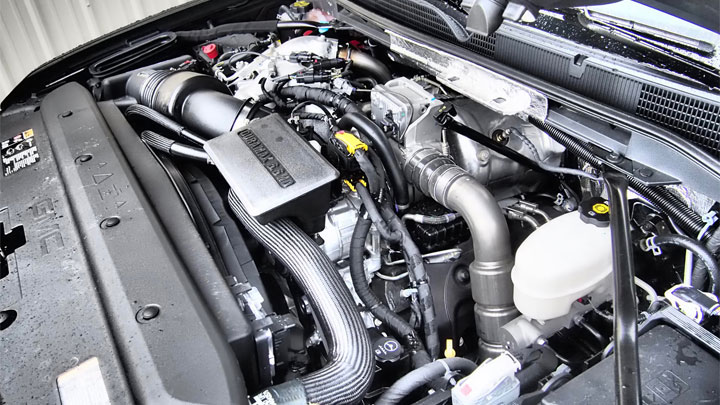

The critical components of a common rail diesel engine include:

- High-Pressure Pump – Builds the fuel pressure required for injection.

- Common Rail – A high-pressure fuel reservoir.

- Injectors – Precision valves that deliver the fuel into the engine’s combustion chamber.

These components work coherently to furnish the diesel engine with the fuel in a highly controlled manner.

Operating Principles

A common rail diesel engine operates on a principle of maintaining fuel at a high pressure within the common rail.

This fuel then gets delivered to the injectors as needed. The system’s ability to control the timing and amount of fuel injected into the engine’s cylinders contributes to:

- More efficient combustion

- Reduced fuel consumption

- Lower emissions

By keeping the fuel at constant high pressure, injections can occur at any point in the engine cycle, providing you with flexibility in the injection timing, duration, and rate.

Advantages of Common Rail Diesel

Common Rail technology revolutionizes diesel engines with substantial enhancements across various performance metrics.

#1 – Better Performance

An engine’s performance is significantly improved with Common Rail systems.

By delivering fuel at high pressure and with exact timing, the technology provides a faster and more complete combustion. This translates to increased power and acceleration in your vehicle.

#2 – Fuel Efficiency

Fuel efficiency is a hallmark of Common Rail systems.

These systems use precision to optimize fuel delivery, ensuring less fuel is consumed for the same power output. This leads to greater fuel economy, meaning less trips to the fuel pump.

#3 – Emissions Reduction

Simply put, you contribute to a cleaner environment with reduced emissions.

Common Rail technology is adept at emission control, cutting down on harmful pollutants. This is achieved through more efficient fuel combustion, leading to fewer particulates and soot in the exhaust.

#4 – Noise Reduction

Appreciate a quieter diesel engine experience.

The precise injection timing and smoother operation of Common Rail systems result in lower noise levels, which makes for a more comfortable ride.

#5 – Precision and Control

Precision and control are at the forefront of Common Rail systems.

They allow for precision in fuel injection timings and quantities, ensuring reliability in performance and aiding in maintaining consistent engine quality and diesel technology innovation.

Common Rail Diesel Disadvantages

While common rail systems offer quite a few benefits, they also come with some drawbacks:

- Cost – Common rail systems are generally more expensive to manufacture and install compared to traditional fuel injection systems. This can result in higher vehicle costs.

- Maintenance – The high-pressure components and precision engineering required for common rail diesel engines can lead to higher maintenance costs and more complex repairs when issues arise.

- Durability – The high-pressure operation of common rail systems can potentially lead to increased wear and tear on engine components over time, which could affect the engine’s longevity.

Common Rail vs Direct Injection

Common rail systems use a high-pressure fuel rail that supplies fuel to solenoid valves, which in turn control the delivery of fuel to each injector. This system allows for more precise control of fuel injection timing and quantity, which can lead to improved fuel efficiency, lower emissions, and better performance.

The common rail system can also produce less noise compared to traditional direct injection systems, resulting in a better driving experience.

Direct injection, on the other hand, injects fuel directly into the combustion chamber of each cylinder. This method can be more fuel-efficient than older indirect injection systems because it eliminates the need for fuel to “swirl” in a pre-combustion chamber, which can sap energy.

Overall, common rail systems are generally considered by most experts to be superior for most diesel applications due to their improved efficiency and performance capabilities.

However, the best choice between common rail and direct injection may depend on specific engine designs and the goals of the engine manufacturer.

Common Rail System Components

A common rail diesel engine relies on advanced components that work in unison to deliver precise quantities of fuel at high pressures.

Fuel Injectors and Nozzles

An engine’s performance is greatly influenced by the fuel injectors, which precisely deliver fuel into the combustion chamber.

Equipped with either solenoid valves or piezoelectric valves, these injectors open and close at high speeds, allowing for accurate control over the injection timing and quantity.

Attached to the injectors are the nozzles. These finely crafted components are responsible for spraying fuel into the engine’s combustion chamber in a specific pattern, which is crucial for effective air-fuel mixing and clean combustion.

High-Pressure Pump

The high-pressure pump is the heart of the common rail system, tasked with compressing fuel to pressures that can exceed 25,000 psi.

This makes sure the fuel is atomized to an extremely fine degree upon injection, a key factor in the system’s efficiency and performance.

Fuel Rail and Pressure Accumulator

Acting as a manifold, the fuel rail is where high-pressure fuel is distributed to the injectors. It’s engineered to handle extreme pressures, maintaining consistent performance across various engine conditions.

Within the fuel rail lies the pressure accumulator, which is designed to dampen fuel pressure fluctuations, thus providing a steady supply of pressurized fuel to the injectors for accurate and consistent fuel delivery.

Engine Control Unit and Sensors

The Engine Control Unit or Module (ECU or ECM) is your engine’s brain. It receives data from various sensors regarding engine speed, load, temperature, and more.

The ECU processes this data to dynamically adjust fuel injection timing, duration, and pressure, using sophisticated electronic engine control strategies to optimize performance and emissions.

Injection Process and Timing

Two pivotal aspects for peak performance are the management of the injection pressure and the precise control of the injection timing and rate. Your engine relies on these factors to achieve proper combustion and power output.

Injection Pressure Management

In a common rail diesel engine, fuel injection operates under high pressure to optimize the spray pattern and improve fuel atomization within the combustion chamber.

The electronically controlled system precisely regulates this pressure, which can be upwards of 25,000 psi, to accommodate varying engine loads and conditions.

Monitoring and adjusting the injection pressure optimizes engine efficiency and reduces emissions.

Injection Timing and Rate

The timing at which fuel is introduced to the combustion chamber is crucial. Your engine’s ECU calculates the perfect moment for fuel injection, considering factors such as engine speed and load.

Direct injection allows for precise control of the amount of fuel delivered and the duration of injection, known as the rate, ensuring that you get the right amount of fuel at the right time for optimal combustion.

Multiple Injection Events

A common rail system is capable of performing multiple injection events during a single combustion cycle.

This could include a pre-injection to prepare the combustion chamber, the main injection event for power, and a post-injection to reduce emissions or clean the particulate filter.

Environmental Impact and Emissions Regulations

Your understanding of common rail diesel engines must include their environmental footprint, particularly in terms of emissions output.

It’s imperative to consider how these engines meet regulatory standards, reduce particulates such as soot, and the role of aftertreatment systems in mitigating environmental impacts.

Meeting Emissions Standards

Owners of diesel vehicles should be aware that diesel particulate matter and nitrogen oxides are the main emissions produced, both of which are harmful to human health.

To address this, strict emissions regulations have been imposed globally, necessitating advancements in diesel technology.

For example, modern common rail diesel engines have evolved to meet these standards by offering precise fuel injection control, which contributes to reduced nitrous oxide emissions.

Particulates and Soot Reduction

Soot and particulates emitted from diesel engines are a major environmental concern. With common rail technology, you get a more efficient combustion process that results in lower particulate emissions.

To further reduce these emissions, diesel engines employ particulate filters that capture soot particles, which are then periodically burned off during the engine’s regeneration phase.

Aftertreatment Systems

The aftertreatment of exhaust gases is another important step in curbing emissions.

Most diesel engines use systems such as Selective Catalytic Reduction (SCR) and Diesel Particulate Filters (DPF). These systems are designed to remove harmful emissions post-combustion.

The SCR converts nitrogen oxides into nitrogen and water vapor, while the DPF traps particulate matter, which is periodically oxidized to prevent clogging.

Common Rail Systems in Different Vehicle Makes

While common rail systems have revolutionized fuel injection in diesel engines, different major manufacturers have adopted and tailored these systems to their specific vehicle makes and models.

Cummins Engines

Your Cummins engine benefits from an advanced common rail system that ensures efficient fuel delivery and optimal performance.

Cummins started incorporating the common rail system into their engines in the early 2000s, allowing for quieter operation and reduced emissions.

Bosch Systems

Bosch is synonymous with innovation in automotive engines, and their common rail systems are a testament to this.

You’ll find Bosch common rail systems in various vehicle makes, as they’re one of the primary suppliers of this technology. Their high-pressure fuel pumps and precise injectors deliver fuel efficiently.

GM’s Duramax

If you drive a GM vehicle, it’s very likely powered by the renowned Duramax engine, which employs a common rail system to increase performance. At the same time, common rail diesel is why Duramax powered trucks are known for their excellent gas mileage.

General Motors collaborates with Isuzu to produce these engines, combining robust powertrain engineering with common rail fuel injection technologies.

Dodge’s Powertrain

Dodge’s heavy-duty trucks, specifically those in the Ram lineup, are equipped with a powertrain that uses the common rail system.

This inclusion has allowed Dodge to maximize the power output and fuel efficiency of their automotive engines, especially in their Cummins-equipped models.

Future Trends and Innovations

The landscape of common rail diesel engines is rapidly evolving, with a distinct push towards higher efficiency, lower emissions, and greater performance.

The integration with hybrid technologies, electronic control advancements, and injector design improvements stand at the forefront of this innovation wave.

Integration With Hybrid Technologies

Common rail diesel engines could soon be paired with hybrid powertrains—combining the benefits of diesel’s high torque and efficiency with electric motors’ responsiveness and emission-free operation.

This integration aims to further improve fuel economy and reduce overall emissions while maintaining the robust performance you expect from diesel engines.

Advancements in Electronic Controls

The latest advancements ensure precision in managing fuel pressure and injection timing for direct fuel injection systems.

As these controls become continue to evolve and get more sophisticated, modern diesel engines will also continue to benefit.

Improvements in Injector Design

Injectors are pivotal in common rail systems, and their design is continuously improving.

With a focus on achieving higher fuel pressure and more flexible fuel delivery, modern injector designs allow for finer atomization of fuel. This precision leads to cleaner, more efficient combustion, yielding performance enhancements across a diverse range of operating conditions.

- Replace the Engine or Replace the Car? (11 Factors to Consider) - Apr 11, 2024

- Plastic Piece Dragging Under Your Car? (What It Is and What To Do) - Mar 21, 2024

- Timing Belt vs Timing Chain (What’s the Difference?) - Feb 27, 2024

I had just under a 1/4 tank and filled my diesel truck up with 3/4 of unleaded and drove 15 miles before it really began to struggle a bit. I shut it down and had it towed..what am I looking at? Shoot me straight..2021 Ram 2500 6.7L Cummins

That’s not good. At a bare minimum you’ll probably want to drop the tank and flush the fuel system. I don’t know if any engine damage resulted. Fortunately, 15 miles isn’t very far before you noticed. I think you did the right thing by having it towed.