4 Symptoms of a Bad Rocker Arm (and Repair Cost)

That annoying ticking coming from under your hood likely isn’t your imagination. A malfunctioning rocker arm is often the cause of this worrisome sound.

Keep reading to learn about the common signs of a failing rocker arm and what it’ll cost to get it repaired or replaced.

What is a Rocker Arm and How Does It Work?

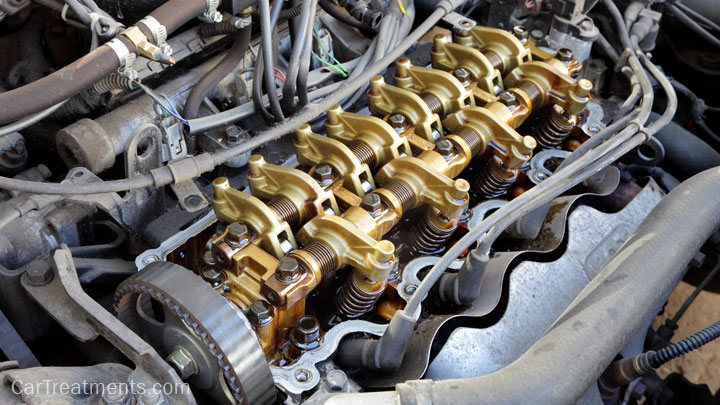

Rocker arms are typically located between the pushrod and intake and exhaust valves. They are pushed and pulled by pushrods to “rock” up and down, opening and closing the exhaust valve and intake valve of the combustion chamber on engines with a camshaft below the engine.

Pushrods move up and down as the camshaft below them rotates, driven by the crankshaft. In this way, power can flow from the combustion chamber of the engine through various parts to the wheels to put the vehicle in motion.

With broken or loose rocker arms, the exhaust valves and intake valves can’t function correctly and the cylinder associated with the faulty rocker arm will be disabled. This will ultimately limit the performance of your engine and your ability to drive the car smoothly and safely.

Related: SOHC vs DOHC vs Cam-in-Block Engine

Common Symptoms of a Bad Rocker Arm

Your engine may exhibit one or more of the following symptoms if one or more rocker arms is failing. Although, there may be another defective part causing the problem.

Regardless of the cause, the problem should be resolved by yourself or a mechanic before the vehicle is driven again.

#1 – Clicking or Ticking Noises

Unusual noises involving valves often sound like a rapid clicking or ticking, similar to a sewing machine. You should inspect the rocker arms and surrounding parts while the engine is running if you hear this noise. Faulty rocker arms can get stuck or ineffectively open and close the valves.

There are many other possible causes of strange noises in the combustion chamber and surrounding parts, such as lack of lubrication between moving parts, warped valves, and worn camshaft lobes.

If the rocker arms appear to be working well on visual inspection, a bit of troubleshooting done by yourself or a mechanic is the next step to solving the problem.

#2 – Weak Engine Performance or Stalling

Careful timing is everything to a functional internal combustion engine. For maximum efficiency, valves must open and close at just the right time. If the vehicle’s faulty rocker arm is getting in the way of this process, you’ll notice decreased power and poor acceleration.

In severe cases, the engine can suffer to the point of stalling while driving. Eventually, the vehicle won’t even start until the broken component is replaced.

#3 – Check Engine Light On

The vehicle will recognize weak engine performance as well, and will warn the driver by illuminating the check engine light. This signal should never be ignored. You’ll want to use a diagnostic scanner to check for any stored codes.

Some examples of rocker arm related DTC codes include P2646 (A rocker arm actuator system performance or stuck off bank 1), P2647 (rocker arm oil pressure switch), and P2662 (B rocker arm actuator sys stuck on bank 2)

#4 – Physical Deterioration

Visual inspection of the rocker arms can also reveal any cracks or wear. After removing the valve cover, look for pieces of metal below the rocker arms, as they can grind on the pivot point and valves when they are in poor condition.

Degraded rocker arms should be replaced even if no other symptoms are present, because problems will soon follow.

Replacement and Repair Cost

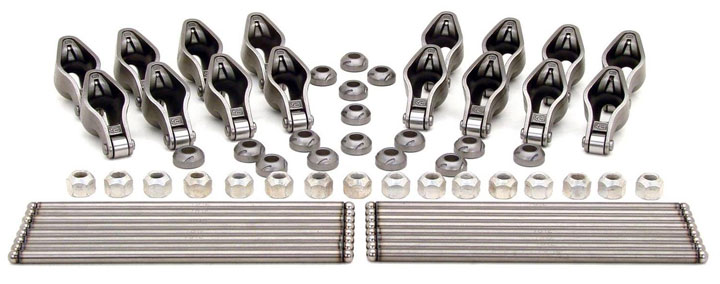

A single rocker arm itself costs between $15 and $60 depending on the vehicle and whether it’s an intake or exhaust rocker arm.

Rocker arm kits, which typically cost between $100 and $500, include other necessary components like guide plates and pushrods, and may be the better way to go if you are confident that you can perform the replacement job yourself.

Often the rocker arms all fail around the same time, so replacing them all at once would be a good idea. This makes the full kits the most common purchase option.

Because rocker arm repair is tedious work, it can be time intensive so hiring an auto mechanic or dealership to do the job is not cheap. Expect to pay anywhere from $500 to $1,500 (parts + labor) depending on the vehicle.

A good chunk of the expense is for labor as it can take a long time to access the necessary parts. Taxes and fees may increase the grand total.

See Also: Bent Engine Valve Repair Cost

Which Type of Rocker Arm to Buy?

Rocker arms are often made from stamped steel, which is basically flat sheet metal that was put through a stamping press and then shaped by a die. Steel is inexpensive while still being strong and fairly lightweight, and thus is a good option for economy cars.

High-performance vehicles usually use aluminum rocker arms, as they are much lighter. Truck engines often require even stronger rocker arms made from forged carbon steel or cast iron.

Some research is necessary to know which rocker arm to purchase if you are doing the job yourself. Automotive parts stores may stock the needed kit for your vehicle, or may be able to special-order parts.

- Replace the Engine or Replace the Car? (11 Factors to Consider) - Apr 11, 2024

- Plastic Piece Dragging Under Your Car? (What It Is and What To Do) - Mar 21, 2024

- Timing Belt vs Timing Chain (What’s the Difference?) - Feb 27, 2024

I have been told that my 2015 Jeep Wrangler needs all the rocker arms (24) and lifters (24 ) replaced the quote was $3,300.00 that seems about twice as much as I see quoted online Am I getting taken?

Where did you get the quote? The dealership is much more expensive than an independent shop.

rocker arm – I had my 2015 malibu towed to the dealership almost 2 months ago! And it is my understanding once the STRIKE was over (I think sometime in November 2019) GM put a hold on manufacturing a list of parts in an effort to catch up the production of other parts they determined there was a greater need. I am sure this pandemic is NOT helping this along any either!!!

I spoke with my mechanic last week and he said he was waiting for an email from an aftermarket manufacturer that is sometimes used. I had tried myself to order the part online and got the run-around… and they won’t warranty the work on a salvaged part.

My car is not the only vehicle at this dealership waiting for this same part either!!!

Again there is no reason a rocker arm should keep ones car on lockdown if you cant find a replacement part you can take one to a machine shop and have it milled and done to tolerances aka specs and away you go now I come from a family of mechanics and mechanical engineers I only trust mechanics who are family sometimes it’s not the cars fault its whom ever you left it with to take care of it

Hey derryl you sound like you know what your talking about have a question for you the timing had skipped in my 07 Dodge Dakota with 4.7 8 cylinder an put new timing set on it an set it to tdc an then I was thinking I might have some bent valves to cause it’s not right the valve lifters are loose on the side that I had damage on my timing the right side or passenger side an so I got new lifters an rockers an they are still loose I can just put them on with my fingers so I think the rods are to short an there not enough there to make them tight why would the rods be shorter now I’m not a mechanic at all I just can’t afford one nor find someone to help me so I’m on my own here can you shoot me a email maybe not sure if you can get back to me on this matter [email protected] thanks in advance bud

My 2015 Chevy Impala has been with the Chevy dealer since SEPTEMBER because it needs a new Rocker Arm and they can’t find the part. What’s more than likely the next step? Full engine replacement? Total it out?

That’s very strange that the dealer is unable to find a part on a car made in 2015. Assuming that is true, it may be possible to find the part online or in a salvage yard.

Have one made by a good machinist perhaps I’d do it myself only I dont have a shop

I also have a 2014 Chevy Malibu that is pulling code P2646. Took the car to one mechanic and he said it’s going to cost me thousands of dollars to repair. Before this mechanic told me that, “he’s like how much do I love my car?”

Another mechanic said, he talked to a dealership and the part needed is on back order and has been. I’m thinking it’s the rocker arm as a few mentioned. Although, another mechanic said, I needed an Oil Pump Flow Control Solenoid. Looking for this part myself, I called a Chevy Dealer and he called the part a Camshaft Position Actuator(Intake) I replaced one a 1 1/2 years ago. I have also replaced 6 wheel bearing hubs. Time to get rid of this Chevy. Any thoughts. The car has 189,500 miles.

I seriously doubt this will cost thousands of dollars to repair. I am inclined to believe the mechanic who suggested the “Oil Pump Flow Control Solenoid” is correct. This is a common cause of the P2646 code and should be relatively cheap and easy to fix; it sits right on top of the engine.

There is a recall because of the rocker arm on our ’14 Malibu with 72k. Check engine light came on. No other symptoms. Still running as new! Going in Monday.

Do you have a picture of that recall notice? I believe my husband threw it away thinking it was junk and now the Chevy dealership says that there is no recall for my ’14 Malibu for that exact same thing…

You should be able to search for recalls here: https://www.nhtsa.gov/recalls

I have a 1996 Chevy k 1500 I’m having transmission problems I had put a junkyard transmission in it it ran fine for a couple weeks and went right back to having the problems I’ve had before and and the problem is the truck seems like it goes to second gear dry financial about 25-30 miles an hour and all the sudden the RPMs skyrocket it won’t go any faster besides rubbing it astronomically and then I can get it to go up to 45 50 but it gets really hot welcome be my problem and why when I changed the transmission just same exact problem happened again there’s a coincidence or is it something else causing the issue thank you very much if you could help me out at all

Sure these automatic gearboxes have a vacuum link, pipe from back of auto gearbox pressure valve via inlet temp control on intake manifold to auto/manual gear changing sensor in dash board close to ecu

if pipe is missed or leaking that part of the ecu that is controller for auto gear box

as has very limited memory once code memory full ecu ignores input from this sensor link,

try battery disconnect for 30 sec to reset your basic ecu codes,

if you get improvement for while you nail this fault,

it will be simple if just crack/leaking vacuum pipes bar get at the bloody one under dash, and changing it , if it the gearbox auto pressure valve ITS A GARAGE JOB AS YOU HAVE TO DISMANTLE WHOLE BLOODY AUTO GEARBOX TO CHANGE IT AND IT COST ABOUT 10 CENTS your money,As its all down to RUBBER O ring wearing and stopping the gear braking system from syncing at right times, Why this sensor was put in dash board and not in engine bay has alway defies logic as its link wire to loom are by the main subframe at back of engine,, Pays to check this main loom links as can corrode inside on pins , THIS CAN CAUSE SOME AUTO GEARBOXS TO START TO SEEM TO FAIL,

On a dodge caravan do anyone knows how much it would cost to get on rocker fixed its by the sliding door

I HAVE A 2014 CHEVY MALIBU AND NEED THE ENGINE VALVE ROCKER ARM ACTUATOR. GM NO LONGER MAKES THEM. WHERE TO GET THE PIECE NOW? CAN’T SEEM TO FIND ONE OR EVEN AN AFTER MARKET ONE. HELP

I also have a 2014 Chev Malibu and need the valve rocker arm replaced and the Chev dealership can not longer find the part.

Take existing good one out and bring it to a machine shop or call around for one and have one fabricated from scratch I’m a machinist and can make anything from scratch given the dimension or specs and tolerances upon application so ya try that my friend

The 2014 Malibu has a recall on the rocker arm oil control valve.

I wonder if this is why my car died and won’t start! I’m getting code P2646. Sounds like my car is out of gas & wont start.

I have a 2013 Ford edge limited not 4 wheel drive and it sounds as if a lifter is knocking but Ford dealership said they can’t be adjusted. It’s not lacking power no rough idle nothing at all just a tick and oil treatment usually quiets it down if not eliminate the sound all together. Should get lifters or rocker arms replaced or deal with it.As a man who is a minor mechanic and a DIY it drives me bananas

I have the same issue, what was your resolution?

Hi I have a 2010 charger 3.5 I had the tick I just went and got new rocker arms and installed. Upon completion started the car and it sounds worse than when I started….I can’t figure out what I did wrong. Any advice.

Sounds like you need a new engine or a rebuild..MAYBE A ROD BENT

Maybe you lifted the cam too high causing a timing problem…

Replacing on the 3.6 Pentastar is a piece of cake, and only cost about $8.50/ea at the dealership.

Piece of cake? Please describe step by step and necessary tools