4 Symptoms of a Bad Wastegate (and Replacement Cost)

Turbochargers promise powerful performance, but when the internal wastegate fails, that power turns to problems.

Learn the typical symptoms of turbocharger wastegate failure (some of which can be rather alarming), what causes it, and how much it’s going to cost to repair or replace your wastegate .

What Is a Turbo Wastegate?

A turbo wastegate is a critical component found beneath the hood of vehicles equipped with turbochargers.

It’s used to regulate maximum turbocharger turbine speed, in turn governing overall boost production as a whole. As a result, the chance of developing an overboost condition within an engine’s forced induction system is greatly reduced.

How a Wastegate Works

To better understand the process outlined above, you must first familiarize themselves with the basic principles of turbocharger operation. A turbocharger utilizes exhaust energy produced during the combustion process to spin a specialized turbine wheel used to direct pressurized air into an engine’s intake tract.

This oxygen-dense intake air is ideally suited to producing more volatile combustion, especially when additional fuel is dosed to each respective cylinder.

A wastegate regulates turbocharger turbine speeds by redirecting excessive exhaust energy away from an engine’s turbo, under specific conditions. Simply put, the maximum energy acting upon the control (exhaust) side of a turbocharger’s impeller shaft is effectively limited by its corresponding wastegate, in turn, holding peak boost pressures in check.

Turbo wastegates come in several different forms and can consist of either an internal or external arrangement, depending upon the application. Regardless, most turbocharger wastegates include a spring/diaphragm arrangement, which is acted upon by pressurized air distributed through an attached sensing line.

Here’s a good video on how both internal and external wastegates work:

Bad Wastegate Symptoms

When a turbocharger wastegate fails, a number of secondary symptoms can arise, some of which tend to be more concerning than others. Recognizing such symptoms can prove key when attempting to expedite the repair of the issue at hand.

The following are several of the most common symptoms associated with a bad wastegate.

#1 – Illuminated Check Engine Light

In most instances, wastegate-related issues will lead to the illumination of a vehicle’s check engine light. This stems from the fact that an engine is unable to achieve manifold pressures as desired, while in operation.

An OBD2 scan tool should be used to discover what specific diagnostic trouble codes (DTCs) have been stored by vehicle’s ECM to help confirm whether it’s a wastegate issue. A few examples of codes related to a wastegate include: P0234, P0243, P0244, P0245, and P0250.

#2 – Lack of Sufficient Boost

When a turbo’s wastegate is stuck open, exhaust gasses are dumped, rather than being directed through the exhaust side of an engine’s turbo. As a result, boost pressures are greatly reduced.

#3 – Reduced Fuel Economy

Additionally, when a wastegate is stuck open, excessive fuel will be burnt in an attempt to achieve the expected engine output. However, this desired level of output will never be achieved, due to insufficient intake air delivery.

#4 – Erratic Boost Pressures

When a turbo wastegate is stuck closed, the risk of engine overboost rises dramatically. As a result, erratic or excessive boost pressure gauge readings are often registered. If this condition is not quickly remedied, severe engine damage can result.

Causes of Turbo Wastegate Problems

Turbo wastegate failure can be caused by a host of underlying issues, a number of which are not always easy to pinpoint. However, learning to address such issues can be critical when attempting to prevent reoccurring wastegate failures.

The following are several of the most common causes of turbo wastegate failure.

#1 – Carbon Build-up

In certain instances, a wastegate can experience failure due to carbon fouling. As exhaust-generated carbon contaminates a wastegate’s internal diaphragm, bypassing often results.

In the most extreme of cases, this carbon contamination can even cause a wastegate’s internal diaphragm to rupture.

#2 – Weak Actuator Spring

A turbo wastegate can also fail from normal wear and tear, as its actuator springs begin to age. When this occurs, a wastegate might begin venting unexpectedly, causing erratic boost pressures.

#3 – Misadjustment

At times, both internal and external wastegates can require adjustment. The procedure for accomplishing this varies by wastegate configuration. A misadjusted wastegate can lead to a number of operating abnormalities.

Replacement and Repair Cost

The cost of turbocharger wastegate repair or replacement can vary significantly from one model of vehicle to the next.

This stems most prominently from the fact that some external wastegates are far more easily repaired than their internal counterparts. This fact alone can make estimating wastegate repair/replacement costs quite difficult.

Generally speaking, you can expect to pay between $200 and $600 to have your vehicle’s turbocharger wastegate repaired or replaced. However, if the failed wastegate itself necessitates turbocharger replacement, this cost effectively skyrockets, often totaling $2,000 or more.

Where Is the Wastegate Located?

There are two different types of turbocharger wastegates in use today; internal and external.

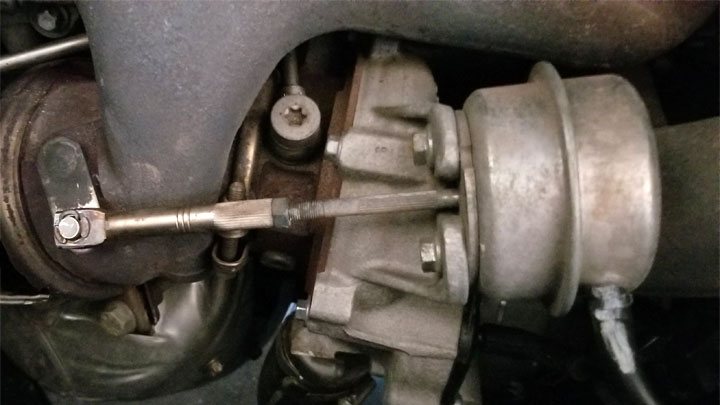

As their name would suggest, internal wastegates are situated within the turbocharger itself, most prominently affixed to the turbine housing. Wastegates of this style typically feature a pneumatic actuator, flapper valve, crank arm, and rod end.

Alternatively, some turbochargers feature externally-mounted wastegates, which are positioned between an engine’s exhaust manifold, and a turbo’s inlet-side turbine housing.

This style of wastegate moderates inlet air consumption by diverting incoming exhaust gasses, in the case that boost pressures exceed their rated threshold.

Wastegate vs. Blow Off Valve

Wastegates and blow off valves are both designed for use with turbocharged engines and serve to reduce the chance of incurring overboost. However, the manner in which each of these two components is used differs slightly from one another, most notably in terms of where each is located.

As previously mentioned, wastegates are positioned ahead of the turbo, along an engine’s exhaust manifold, or alternatively, in the turbine housing of a turbocharger itself.

On the contrary, blow off valves are positioned in an engine’s intake tract, downstream of the turbo itself. These devices vent excess boost pressure, rather than preventing its build-up, like a wastegate.

See Also: Turbocharger vs Supercharger (Which is Better?)

Do All Turbocharged Vehicles Have Wastegates?

Turbocharged engines and wastegates go hand-in-hand, with the vast majority of turbocharged engines featuring a wastegate of one particular type or another. That being said, there are a few exceptions to this general rule, the most prevalent of which pertains to newer, more advanced variable geometry turbos.

The variable geometry turbocharger is unique, as it provides many of the same charge-limiting capabilities, without the use of a dedicated wastegate.

Turbochargers of this type feature specialized vanes on their exhaust side, which move in response to varying operating conditions. This movement redistributes the flow of incoming exhaust gasses, thereby moderating turbocharger speed as a whole.

Read Also: What Exactly Is a Spoon Engine?

Can You Run a Turbo Without a Wastegate?

Most turbocharged engines in production today utilize wastegates of some form or fashion. This is due to the fact that wastegates serve as an engine protection device of sorts, preventing overboost from occurring.

Without this level of protection, severe engine damage could occur, as a turbocharged engine reaches its maximum RPM. While, theoretically, it is possible to operate a turbocharged engine without a wastegate, doing so would prove largely impractical.

To accomplish this feat, you’d be forced to find the perfect turbo for your specific application, that only reaches an engine’s maximum boost threshold, when an engine has reached maximum RPM.

Since this prospect is largely unattainable under real-world conditions, wastegate usage is deemed necessary.

What Is Wastegate Rattle?

Wastegate rattle is a condition in which a persistent “jingling” or “chirping” is emitted from an engine’s turbocharger. This noise is most commonly heard when at idle, yet is sometimes also audible during periods of light acceleration. Wastegate rattle is more prevalent in higher mileage engines in most cases.

Much like many other turbocharger-related issues, wastegate rattle is most often attributed to extensive wear and tear that accumulates over the length of a turbo’s service life.

This “rattle” originates in the wastegate itself, and arises courtesy of worn bushings and actuator rod ends found therein. As a result of this wear the wastegate no longer seats firmly, thereby causing an audible rattling.

- P0480 Code (Symptoms, Causes, and How to Fix) - Apr 19, 2024

- Car Temperature Gauge Stopped Working? (Here’s Why) - Apr 15, 2024

- Ignition Coil vs Coil Pack (What’s the Difference?) - Apr 8, 2024